Question 1 / 8

How has their performance been so far?

Quality:

On-time shipments:

Service & attitude:

Why does supplier performance matter?

Maybe you track performance data. Maybe not. In any case, you can probably tell if you are happy about your manufacturer's past performance record.

Here are examples of common issues:

- Inconsistent quality, with relatively frequent quality accidents that impact your business

- Average proportion of defectives is high

- Frequent shipment delays

Slow response to requests (poor service)

Question 2 / 8

When a problem comes up, do they address it well or are they stuck in fire-fighting mode?

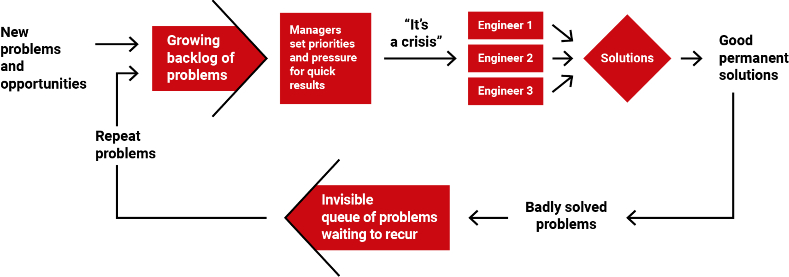

Why is regular fire-fighting damaging?

Does your manufacturer seem unable, or unwilling, to conduct proper root cause analyses? Do they fail to follow up on issues? And do the same problems come back?

That's actually a fairly common issue in China. It is the fire-fighting syndrome, as illustrated in the image below.

Source: Stop Fighting Fires, in HBR

In production, every day brings new problems. Because of a lack of competent and empowered engineers, manufacturing managers & supervisors keep getting drawn in the daily fight... and never devote sufficient time to long-term improvement projects.

Question 3 / 8

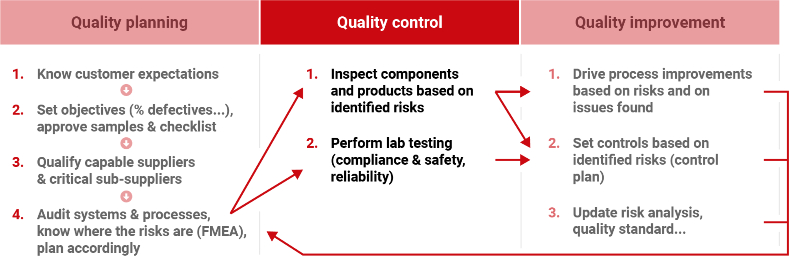

Do they have strong quality management?

Why does a lack of quality management cause trouble?

Many factories only focus on quality control. They skip quality planning and quality improvement. There is no real quality system, no feedback mechanism, no effort at upgrading the systems and processes.

Note: this concept is loosely adapted from Juran's Trilogy.

The whole operation is chaotic. As explained in the previous point, people are busy reacting to issues. When one key engineer or supervisor leaves, the fragile balance crumbles and serious issues develop unchecked.

Question 4 / 8

Is top management involved in the operations?

Tell me more about how poor management can cause negative effects?

Where do all issues come from, at the end of the day? From bad management. And there are many ways to spot this.

Question 5 / 8

Have prices gone up without clear explanations?

Why are unexplained prices rises bad news?

Has your manufacturer been pushing hard for price increases? It is typical for Chinese suppliers to do this by invoking their rising costs.

While it is true that wages have risen continuously for the past 35 years, that's not the case of raw materials, fabricated components, rental fees, production equipment, and other key cost drivers.

If your purchasing budget is in the hundreds of millions, you can ask for open-book costing. If you haven't reached that size yet, you can still find factories, like ours, that accept to be transparent on their main cost drivers: cost of each component, number of hours of work.

Question 6 / 8

Do you know the companies making the key components and can you visit them?

Why is a lack of transparency about the component suppliers risky?

Typical Chinese suppliers act as though the information on the components that make up your product is a secret.

And that comes with a number of perverse effects:

- When a problem arises, you can't send your engineers to see how components are made and fix the issue

- Your supplier can switch their own suppliers without letting you know, and that can have a strong impact on quality and timeliness

- When your supplier argues their costs are increasing, you can't check easily whether that's true and what might be better alternatives

- You cannot switch easily from your current manufacturer to a new one

Question 7 / 8

Are you afraid your supplier might become a competitor?

Could you be training a dangerous competitor?

Maybe you have noticed your manufacturer's aggressive presence on trade shows or online B2B directories, and you suspect they showcase your products... or an offer very similar to your products.

Do you want to keep training them, and keep developing your new designs with them? Maybe all you are doing is building a more dangerous competitor.

Question 8 / 8

Is it easy to develop new products with your manufacturer?

Why is a supplier who is poor at product development a troublesome option?

Does it take your supplier a long time to develop a new product? Do they seem unable to grasp some of the specific technologies or processes involved?

Or they can "get things done", but you have to suffer high defect rates and repeated delays on the first batches?

It means your supplier does not have a process for analyzing risks and detecting issues before they impact production (and become costly).

Your manufacturer is causing you a lot of trouble. :(

You are probably already working hard on replacing them with a better supplier.

Your manufacturer is far from perfect.

You may decide to stick with them. However, if you can get the same pricing elsewhere, you probably want to develop a new manufacturer -- if only to have a backup and reduce your risks.

Your manufacturer is not bad.

There might be no need to search for a replacement. However, it might make sense, depending on your purchasing volume and your risk tolerance, to develop a backup source.

So we can get back to you an answer your questions about switching suppliers, please provide the following information for us to know your products and contact you.