What is Fast Tooling Iteration?

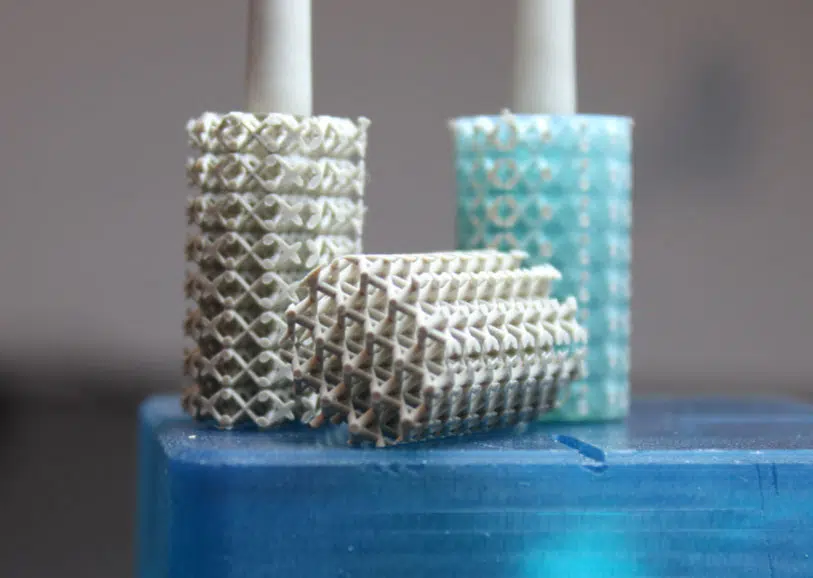

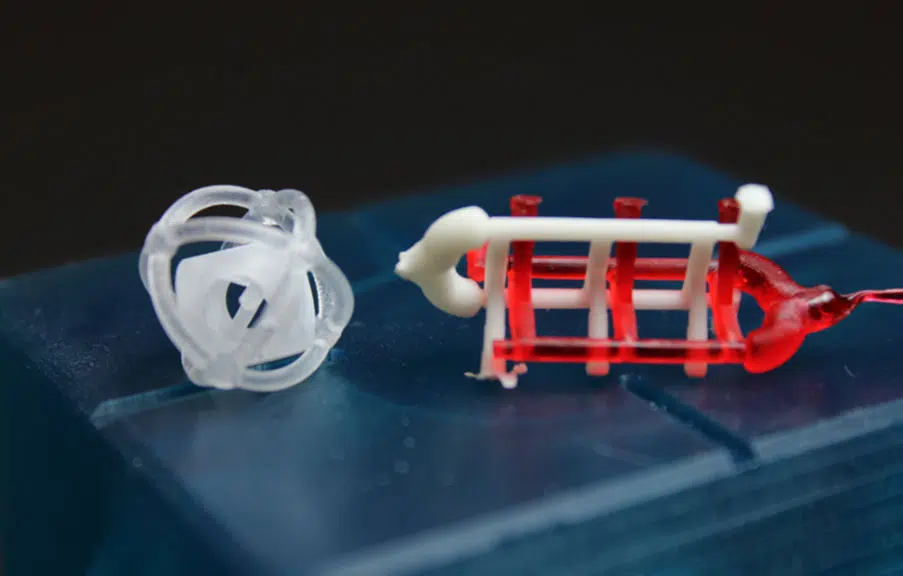

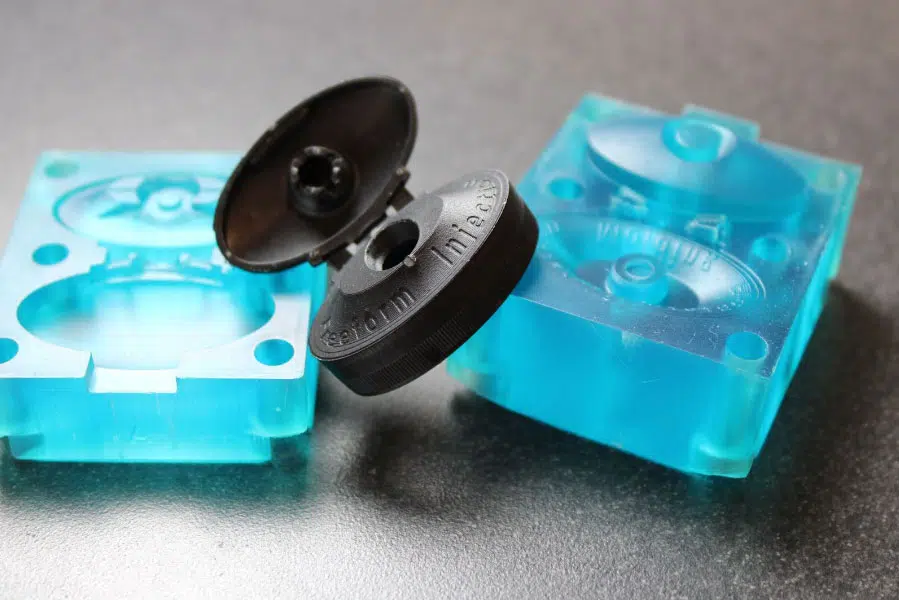

In FTI, a 3D printer creates a mold from a specialized soluble resin. These molds can be designed with intricate geometries that might be very challenging or even impossible to achieve with traditional mold-making methods (using hard metals). Due to the mold material being soluble, it can be dissolved in a special bath after the part is formed, allowing for easy extraction of the final product without damaging complex or delicate features.

We operate the latest version of Nexa3D’s LCD 3D printers, which is the fastest on the market!

Contact us if you want to know how soon we can deliver your first injection-molded prototype, or how little you need to invest to get started.

Keep reading to learn more about our unique offerings in the field of low-volume injection molding.