In this post, we’re going to use a smartphone as an example product (although we work with customers to produce all kinds of mechanical and/or electronic products) and show you what the differences are between working with an ODM supplier to manufacture your phones, and us, a contract manufacturer.

What’s an ODM? (Quick refresher)

An ODM, or Original Design Manufacturer, is a factory that usually specializes in a certain type of product, offers a range of products that are already developed and (hopefully) mature, and allows customers to resell some of those products under their own brand.

Companies and entrepreneurs who lack experience in design and/or manufacturing may find the ODM helpful because they can provide a turnkey solution, simply leaving you to purchase and rebrand finished products which are ideal for your needs.

What’s the catch?

ODMs tend to own the IP and rights to the product because they designed and developed it. By buying their product, even if you rebrand it with your logo, you’re effectively a distributor. This may or may not be a problem depending on your needs, but of course, many companies who import and sell products want to have more control over their products and relationship with suppliers than this.

What is the difference between working with an ODM or Agilian to produce your smartphone?

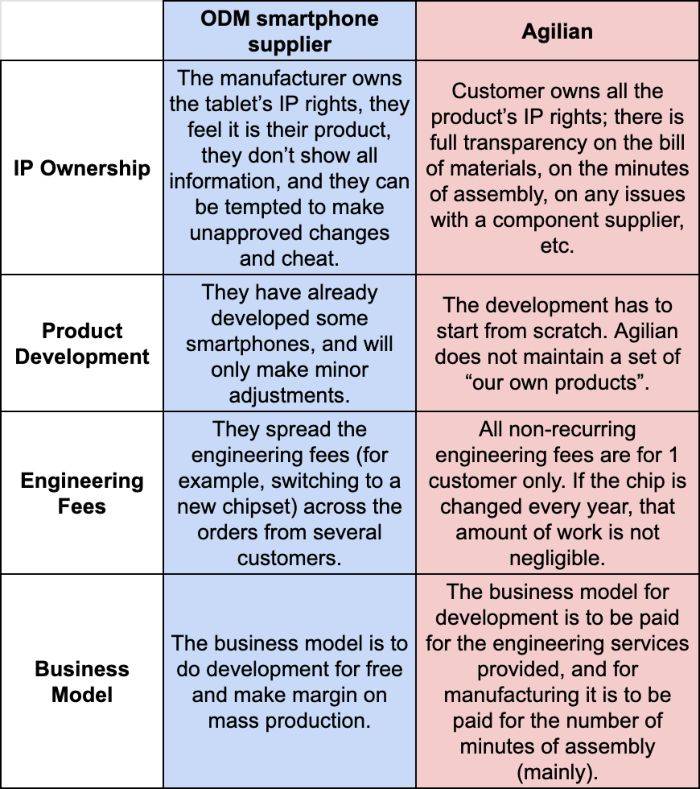

Now that you understand the features, benefits, and drawbacks of working with an ODM, let’s look at the differences between choosing one of those to manufacture your smartphone, and our team here at Agilian:

IP Ownership

This is a big difference because owning the rights to your product provides a lot of security for buyers in future. For instance, if for some reason you want to switch Chinese manufacturers, can you do this if you have no product information to take with you?

Another point to consider is, can you be sure that your ODM supplier won’t develop and produce your product idea, claim the rights to it (having done the work themselves, perhaps understandably), and then start selling it to the highest bidders in direct competition with you?

Product Development

If you choose to work with an ODM who already specializes in your product type, in this case, smartphones, you’re ‘buying experience and a framework’ which should help you get to market quickly because there will be less design, development, and pre-production required before they can start manufacturing. They may even have a finished product ready for you to simply brand or make very minor changes to.

This speed is great for getting to market quickly, but bear in mind that some Chinese ODMs may rush into mass production as quickly as possible as it’s not in their interest to delay or to spend time on making changes to products (redevelopment work) when they get paid for finished products.

This is almost the opposite with a Contract Manufacturer like Agilian. We start the process from scratch at whatever point you’re at, for example, if you already have completed some of the product designs, we start from there. By necessity working with a CM will be more involved than with an ODM, as more work is required throughout the new product manufacturing project, from sourcing parts to testing, to manufacturing, but you do have total control over the process and are able to develop and produce a truly unique product which may be challenging with an ODM who is very likely to be disinterested in doing a lot of new product development work on their existing designs.

There will be no rush and no stone is left unturned to produce an excellent product because, as a CM, we’re paid for work done, so it’s not an incentive to get products made ASAP, meaning that Agilian does as thorough a job as possible at any stage.

Engineering Fees

These NRE fees can add up as product engineering can be a costly process requiring hours of labor from highly-skilled engineers. Both ODM and CM will do this work, but because ODMs deal with numerous customers the cost is spread out, whereas with a CM they work on your unique project meaning that the costs fall on your shoulders.

The benefits of either approach really depend on where you’re at with your business and your needs. New to manufacturing and producing relatively simple or generic products where controlling IP isn’t so much of an issue? Then the lower engineering costs of an ODM may be appropriate. In other cases, the control over your IP and project make the extra costs worth paying.

Business Model

ODMs are focused on mass production as they’re usually paid for completed orders. They will have performed the costly product design and development earlier and then aim to claw back these costs by selling those products over and over to different customers. You can see that redeveloping their existing products wouldn’t be attractive for them as this is directly against their model, so aside from perhaps adding a brand or changing a colour, wholesale product changes to provide a unique product for you are unlikely. The drive to get into production can, arguably, lead to less attention being paid to product quality, for example, too.

A CM is paid for all work done, so there’s no particular incentive for them to spend any less effort on any task in order to get products shipped quickly. This means that, although overall costs of working with a CM like Agilian could be higher than working with an ODM, the benefits provided are worthwhile, such as:

- Total control over the project and what the CM does and does not do

- You own 100% of the IP, even if the CM does the design, development, and product engineering for you using their in-house expertise

- No production steps are rushed that should lead to higher quality, fewer recalls, superior safety, and better compliance

So, who are you working with?

You may find this episode from our parent company’s podcast helpful in better understanding the different types of Chinese suppliers out there:

What type of supplier do you have experience of working with? Do the benefits and drawbacks we’ve described here ring true in your experience? Have you made a switch from ODM to CM before? Let us know by commenting, please.

Learn more about how working with a Contract Manufacturer like Agilian works and what goes into the cost you pay here…

This page outlines the structure so you understand what we charge for and what goes into our pricing:

For a precise quotation, please contact us. (We will need specific information about your product.)

About Renaud Anjoran

Renaud is a recognised expert in quality, reliability, and supply chain issues and is Agilian's Executive VP. He has decades of experience in electronics, textiles, plastic injection, die casting, eyewear, furniture, oil & gas, and paint. He is also an ASQ-Certified ‘Quality Engineer’, ‘Reliability Engineer’, and ‘Quality Manager’, and a certified ISO 9001, 13485, and 14001 Lead Auditor.