Developing an innovative hardware product is a complex project. And most of those projects take much longer than initially planned.

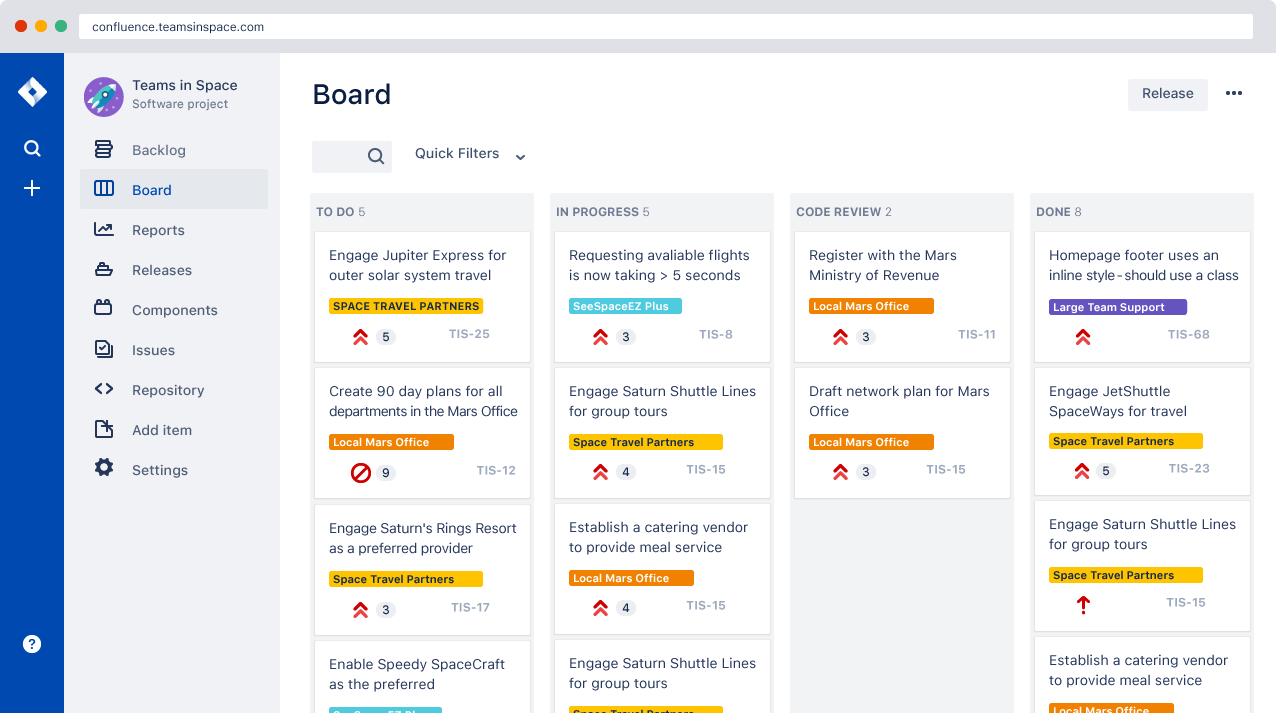

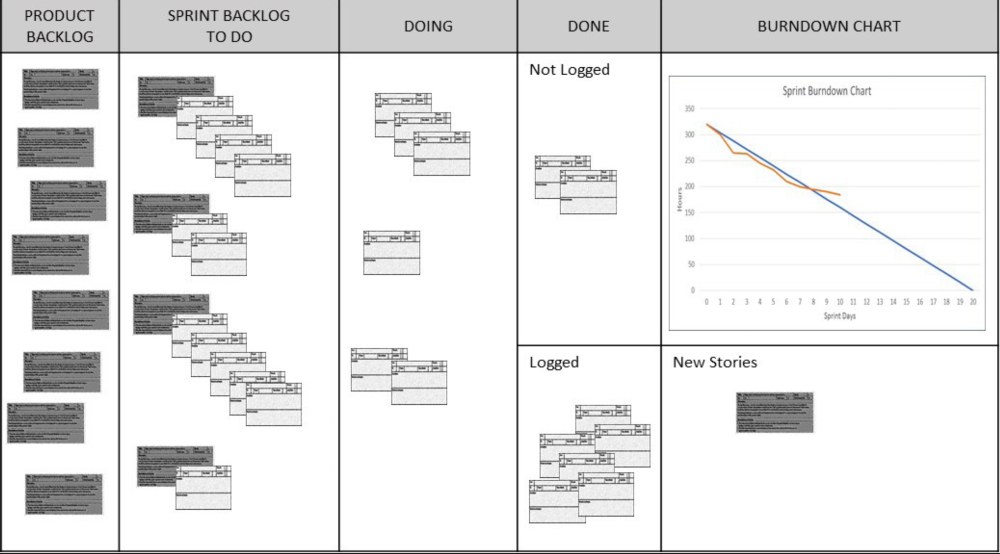

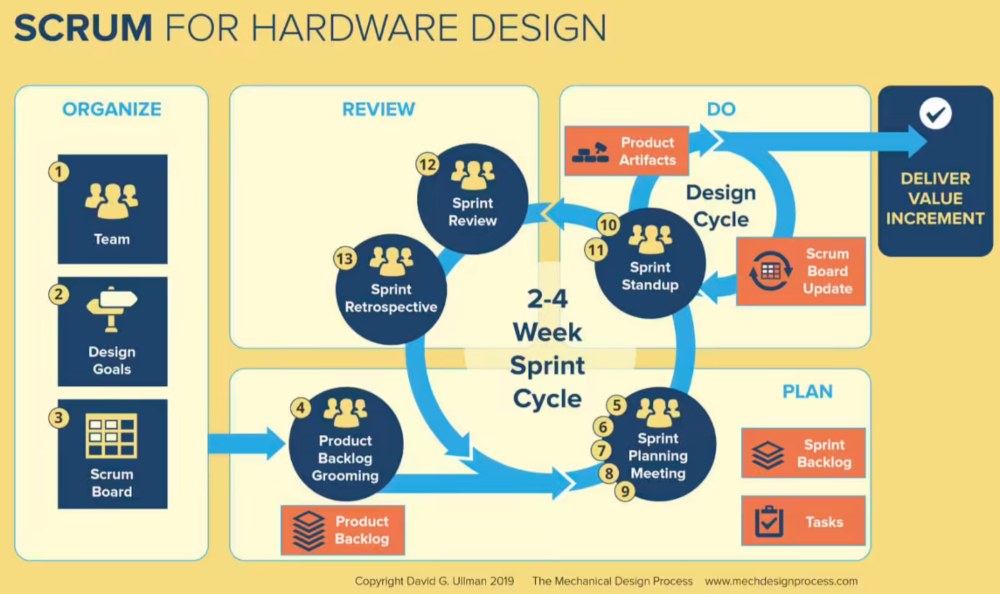

These days, it seems most software development teams have adopted agile principles, and often a variation around the “scrum” methodology. And a small but growing number of hardware development teams have also adopted a ‘SCRUM for hardware’ approach with good results.

How does it work, and why does it prevent delays in getting a new product “from idea to final prototype”? This is what we explain in this article.

Get help today

If you have any questions about the SCRUM for hardware approach to new product design and development or are looking for advice about bringing your product to market, get in touch with us. We’ll be happy to get you started with some advice and explain how we might be able to support your project.