In this post, we’ll explain why access to your Bill of Materials (BOM) is so important, why some Chinese manufacturers like to keep it a secret, and why we prefer an open BOM.

What is in the Bill of Materials?

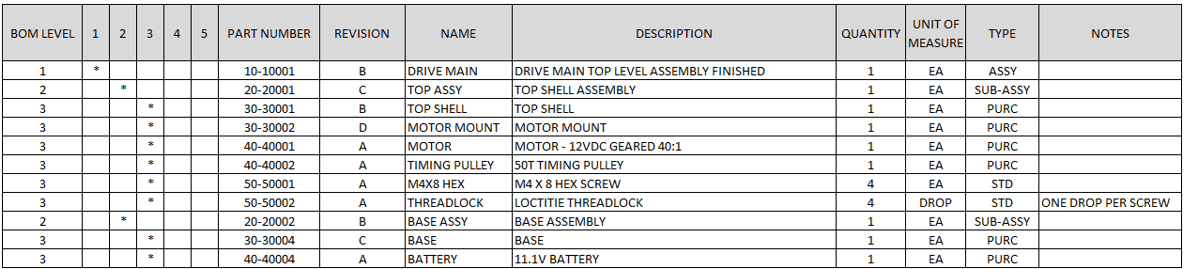

The Bill of Materials, or BOM, is the list of components and materials required to manufacture a product and will commonly include price, supplier, and quantity information.

A Bill of Materials usually includes the following:

- BOM Level – This indicates the level of the assembly or part within the hierarchy

- Part Number – Every element of the BOM needs to have a unique part number including assemblies and sub-assemblies.

- Revision – This indicates what revision level is currently being used in production

- Part Name – this is the short form name of each part or assembly

- Description – This is the part or assembly description which gives more detail about the part

- Quantity – Each part can be used a number of times in the assembly, each part needs to be listed in the correct assembly and the quantity is shown for each assembly

- Unit of Measure – This defines the measure in which each part is to be used or purchased, for example, each, kg, drops.

Other options fields could include:

- Type – This defines if a part is made in-house, purchased off the shelf as a standard part, or sub-contracted out for manufacture

- Part Reference – This can be used to identify where a part is used or the type of part it is, for example, PCBA, Hardware, Code

- Notes – This is just an area against each part where specific notes can be added which can help those using the BoM

- Price – The current purchase price

And, of course, it identifies the source of each part and the basic commercial information:

- Supplier company name & contact info

- MOQ (minimum order quantity)

- Lead time

- Payment terms

This is an excerpt from an example BOM so you can see what it would look like:

Why having the BOM is so important

A lot of manufacturers in China don’t like to share the Bill of Materials with their customers, as they see their business contacts and suppliers as their IP, especially if they have done the sourcing work. Unfortunately, this results in many customers not having access to information about their product’s materials and components, or who supplies them. There are so many reasons why you should be able to see your BOM, here are just a few:

- You have visibility over your supply chain (which is increasingly important because of regulations that force importers to conduct due diligence on their suppliers and in some cases their sub-suppliers and so forth)

- You know what materials and components cost, their lead times, their MOQs, etc.

- Your manufacturer doesn’t have too much leverage over you and has a lower ability to lock you into working with them

- You can switch to a new manufacturer and retain some of the various suppliers should you need to

As you can see, there’s no downside to having the information about your product in your own hands!

We prefer an ‘open BOM’

An open BOM is a BOM that you have access to. A transparent manufacturer will provide this, and you may also add it as a requirement in your manufacturing agreement.

The spreadsheet will include your different suppliers, and you should note that we usually work with 2 or 3 suppliers for common components (such as plastic parts that are injection molded, PCBA, and so on) because different projects come with different requirements (quality, speed, cost…) and 1 supplier can’t satisfy all. It’s also good to introduce some competition with new candidates, as sometimes the usual suppliers get busy and their quotes start creeping higher and higher.

When the project manager does the study, they clarify what suppliers we have been cooperating with, of course, and we point to the known risks that come with each option. We believe our customers should know everything and be part of the decision.

In the end, do you want them to be our suppliers (and you don’t know them) or your suppliers (so you can contact them, visit them, etc.)?

Of course, we have to make the purchase from them to comply with Chinese laws, but the relationship is much healthier and more equal if there is an open BOM.

Information is power

What do I mean by “your suppliers”? If we underperform to the point where you want to switch to another CM, you don’t need to rebuild the whole supply chain, but instead, you can keep using the same component suppliers.

Most manufacturers in China avoid sharing the whole BOM. With us, you know the unit cost, the lead time, the contact info, and so on.

Having trouble with your manufacturer in China and want to switch to a new one?

We wrote this eBook just for you, and it includes detailed advice & proven processes to prepare and support you to make the switch with the minimum of hassle: