ISTA testing is short for the ‘International Safe Transit Association’ testing. It’s testing done on packaging to make sure that your products are going to get to you in the condition that you expect them to be in if you’re manufacturing overseas. The issue here is that quite a few people are confused about what kind of ISTA testing they should use, so that’s the question that we’re going to answer.

Table of Contents

ToggleLet’s start by making it clear; if you’re not doing this kind of testing you’re very likely increasing the risks of your products getting damaged during transit from the factory to your destination, and this applies to almost any product type, but especially the electro-mechanical products that we often work with. I already explained what ISTA package testing is last year, so let’s now focus on which types of testing you need.

If you’re in the business of shipping products especially from China to the USA or Europe, you need to know about this particular standard which is more of a global standard for package transportation testing. We get a lot of customers who tell us that they don’t really know which one to use based on their product type, size, and packaging.

Why do you need ISTA testing?

Some customers ask us, “Where should I use this type of transportation testing?” Or “Is it applicable to my product?”

As I mentioned it is applicable in many cases, especially in sensitive products like electronics, medical devices, pharmaceuticals, auto parts, and food and beverages, where you need to protect the goods from damage during transportation from heat, cold, humidity, drop, vibration and compression, etc. Think about these product types…If they reach the customer and are defective or fail, this could lead to injury or damage to property, the worst possible outcome for your business. So to avoid this scenario, ISTA testing is a must and provides a great ROI.

So, to select the right packaging for your products, the battery of tests will provide importers with confirmation that their selection is up to the task of protecting what is inside. For example drop, vibration and compression tests, environmental testing like high and low temperature, humidity, and some chemical compatibility tests.

An example of why it’s dangerous to ignore ISTA testing

For your product’s cardboard package, imagine you didn’t know how much weight the thickness of the box type you chose for packaging could handle and they got open for some reason due to the vibration of transport and some liquid stored inside came out, or humidity made the boxes soggy and they collapsed crushing the products inside. That’s just two examples that could be avoided by performing ISTA testing because you can bet that if one box gets damaged during transport, there’s a good chance that many or all would be.

What kinds of testing standards does ISTA provide?

Now that you understand the value of doing this testing, you need to select the correct standard. There are several different types of ISTA test standards whose purpose is to simulate the conditions products and packaging will go through during air, sea, rail, and road transportation. Aside from vibration and drops, remember that shipping containers can get really hot and humid in the middle of the summer, and cold in winter. Also, when they drop that container you never know what’s going to happen in terms of compression and boxes piling up on top of each other inside. Therefore, selected tests ensure that these boxes don’t get damaged during transportation and by the time they arrive at their destination; the goal is for you to receive all your products intact and don’t incur any financial problems or delays in getting them to your customers on time.

There are a few series of ISTA test standards, each stimulating real transportation conditions more than the last. You can see the information for each ISTA test procedure from ISTA’s site, but I’ll summarize them here:

ISTA-1 Series – Non-Simulation Tests

ISTA-1 series are the ones that have the least amount of simulation of transportation so they’re the bare minimum tests that one should choose. According to ISTA, series-1 tests:

Challenge the integrity of the product and package combination. Useful as screening tests but not designed to simulate environmental occurrences.

ISTA-2 Series – Partial Simulation Tests

ISTA-2 series are partial simulations and include additional tests compared to 1. This will be more suited to medium to heavy boxes. ISTA says that series 2 is a:

More thorough screening test useful for refining preliminary designs. Not intended to be predictive of shipping performance.

ISTA-3 Series – General Simulation Tests

ISTA-3 series are the tests that most businesses should go for, as they generally cover the conditions your products will endure during common transportation scenarios, such as air and sea shipping, for example. Confirming this, ISTA states that they:

Provide a simulation of the damage-producing motions, forces, conditions, and sequences of transport environments. Useful as a predictive tool to understand risk of damage.

ISTA-4 Series – Enhanced Simulation Tests

Let’s say you have fragile products like glass or some liquid products, you will probably want to go with ISTA-4 series or some other enhancement versions because these will include the above tests and some others relevant to your product type that are even stricter to reduce the risks of damage. ISTA explain that these tests are quite customized at this point:

Customizing test plans that closely tie the tests and sequence to a user-defined pattern of distribution environment hazards.

What’s the difference between the A, B, C, D, E, F, G, and H procedures?

You will note that ISTA provides different levels of procedure per series, namely A, B, C, D, E, F, G, and H. You can see a few here from ISTA’s site. For example ISTA-1A, etc.:

The point to remember is that the battery of tests increases in intensity and the range of results they will gather as we go up through the letters. For example:

- In the 1A series, you’re typically going to be doing drop, vibration, and compression testing, however, in the 1B series, it’s basically the same but with an added tilt test (which is really more like a drop test but dropped on the corner of the package).

- In the 2A series, you have drop, vibration, and compression, but also an added three more tests over 1A: environmental, low temperature, and high temperature and humidity testing. This already really adds a lot of complexity to to your testing, but if we go to 2B this also adds tilt/corner testing on the drop test which is very tough on your package.

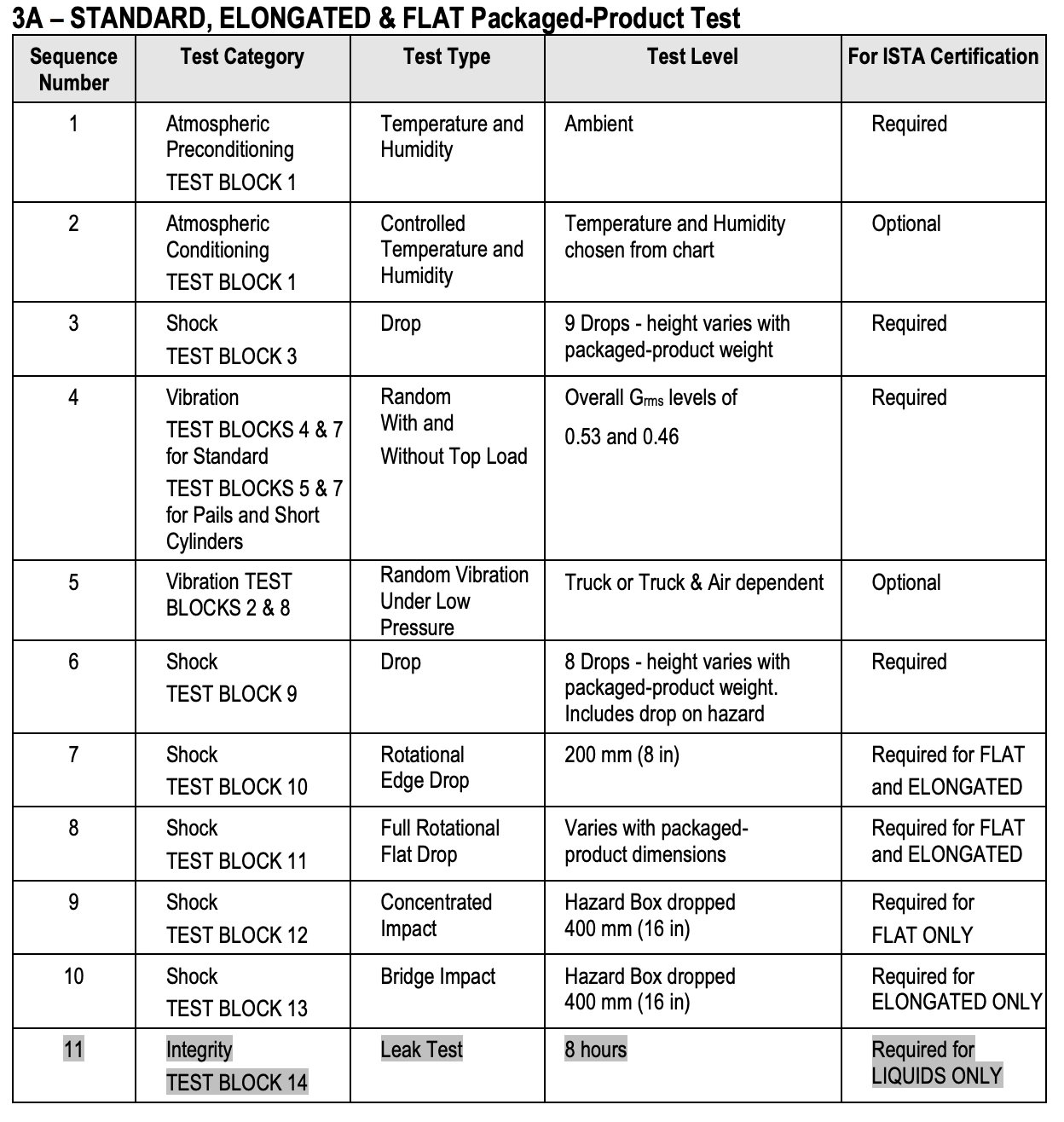

- In 3A you do extensive drop tests which means that the number of drops increases, but also you continue doing vibration, compression climate (high and low temperature plus humidity), and some chemical compatibility testing as standard, but in 3B you also add the tilt/corner test.

Bear in mind that for packages weighing under 150 pounds (68kg), you must select procedures A, C, or G, and for those that are over that weight the others as they’re formulated specifically based on the weights. In fairness, a 150-pound weight pretty much covers most standard packages that people box and ship because a delivery person needs to be able to pick it up and that’s at the top end of a weight someone can be expected to carry.

ISTA-6 Series – Member Performance Tests (FedEx, Amazon)

ISTA 6 is a special testing version specifically for Amazon and FedEx. If you wanted to ship via FedEx or wanted to sell on Amazon it’s highly recommended to put your packaging through this standard’s testing to make sure that they’re compliant with Amazon’s requirements, otherwise, your store could be penalized or even prevented from selling at all.

A tip when selecting your tests

When selecting the ISTA procedure you want to follow, say 3A, make sure that you are using the most recent version. As the years pass, ISTA make changes which can include adding or removing certain tests. If you test to an old version of the standard, you may find that your package is not as durable and protective as you require!

Which ISTA testing is suitable for most products?

There are many options to choose from meaning that importers can zero in on just the right testing. However, in my experience, my recommendation would be to select ISTA 2A testing as this provides a good level of assurance for most products; however for anything more fragile, then choose 3A as that helps ensure that even fairly fragile* products will be protected during the transportation process.

*If your products are even more sensitive or fragile, such as glass, you may choose to select 3B, C, or beyond.

You can see below in this extract from the official ISTA 3A overview that the testing process is quite comprehensive and includes atmospheric, drop tests, vibration, and integrity tests:

The result from your testing lab will be that the packaging is or is not suitable for the products that you wish to ship. Clearly, valuable information for importers to have in hand before shipping any products!

Get help with your testing!

Agilian offers a whole range of different kinds of reliability testing for our customers, including ISTA testing, in our in-house testing laboratory. If you’re unsure about which tests your products or packaging require, get in touch and we’ll talk you through it and provide you with costs and options.