In our earlier blog post, How To Reduce Risks When Developing New Products?, Renaud discussed in a video the risks of not following or skipping steps from a structured NPI process.

You will already have learned that your risks of defects, non-compliant products, going over budget, poor quality, and more, increase. But are there any tangible examples of this?

Well, some unfortunate failed startups made the mistakes so you don’t need to, and we’re going to look at some good examples from Kickstarter and how they went wrong here…

Coolest Cooler

Reason for failure: Lack of DFM.

(Image credit: Kickstarter)

As a product, the Coolest Cooler was wildly popular, but it wasn’t possible to get it into production with the advertised features at the planned price.

The cooler itself included tons of great features, such as an ice maker, waterproof Bluetooth speaker, LED light, USB charger, and more. Sounds perfect, BUT the problem was that they couldn’t go from prototype to mass-produced model. Manufacturing strikes and US tariffs on Chinese products were also cited as reasons the startup failed. However, this isn’t the first product where they made an awesome prototype, but didn’t engineer it to be manufacturable at scale.

The startup should have been ready for manufacturing before launching their crowdfunding campaign. They had not completed the ‘discovery’ phases of the NPI process and were not in the required ‘delivery mode.’

All that excitement and US$13m raised still came to nothing aside from widely being acknowledged as one of Kickstarter’s greatest failures which prompted them to make this somewhat embarrassing statement:

We’ve worked hard to make it clear that Kickstarter is not a store. And in the five years since this project was funded, we’ve taken steps to help creators be more transparent with backers, and to better understand what it will take to bring their project to life. Our goal is to help improve the chances that a project will work out for everyone, with the understanding that the risk will never be fully eliminated.

CST-01 ultra-thin flexible minimalistic wristwatch

Reasons for failure: Lack of component validation and starting production without fixing issues

(Image credit: Kickstarter)

This exciting wristwatch looked promising, but ultimately couldn’t be made at the promised price and failed.

Critical components seemed to be unsuitable suggesting that they had not been validated properly. According to The Verge:

A few months after the campaign’s conclusion, the project detailed its first issues: the need to find a new battery, the need to build a custom battery management circuit, and having to wait longer than expected on other parts.

They battled to produce the 0.8mm thick watch, but it became clear during production that costs would have to double to make them work:

The watches just aren’t easy to make. Little more than half of them are fully working after assembly, according to the two engineers behind CST-01, which means that the costs to make them are effectively doubled unless they can resolve the underlying issues.

In addition, the startup was using Flextronics, or Flex as it is now named (a large and famous contract manufacturer), which is famous for serving Apple, Ford, Microsoft, Google, Dell, and more. This might sound like a great partner, but for a hardware startup counting too much on a big company like this is often a mistake. It may be that their development engineers didn’t develop and validate the manufacturing process properly because this tiny client simply wasn’t a priority for them.

Tiko 3D Printer

Reason for failure: Botched feasibility study.

(Image credit: Kickstarter)

The Tiko 3D printer chose a very immature technology, among other mistakes, and this cost them dearly. The product itself had a lot of promise, as it was a unique portable 3D printer that used a cutting-edge unibody and passive-cooled titanium liquefied. The problem was that these worked well as a prototype, but couldn’t be translated into the mass-produced product; the technology just wasn’t feasible. They also seem to have selected pretty poor critical components, such as the stepper motors, resulting in poor performance.

The question is, did they run usability & performance testing on the product design before launching the crowdfunding? It would seem not. While they did make it into manufacturing and shipped around 4,000 units to North America, the resulting products were plagued with hardware and software performance issues, and the startup failed, leaving a lot of backers out of pocket.

The founders later said (source):

We had no idea how difficult it would be to go from a prototype to mass production. We learned along the way, but most mistakes were costly and irreversible. Our greatest mistake was committing to inventory too soon. We didn’t realize it at first, but by ordering components in bulk, we had backed ourselves into a corner.

Amabrush

Reason for failure: Botched feasibility study

(Image credit: Kickstarter)

The Amabrush was marketed as the world’s first automatic toothbrush that you could insert and clean all your teeth in just 10 seconds. A compelling idea, but it failed because it wasn’t possible to make it at the target price as it required quite complex and costly parts.

Internally they struggled with quality issues (such as bristles falling out) and also material defects which speaks volumes about their design, production, and sourcing processes.

They probably rushed through the prototyping and validation steps because, while some products were delivered, users complained that they didn’t clean their teeth well. It seems that Amabrush couldn’t deliver the promises they made in their crowdfunding campaign for the mass-produced models. Did they actually do a feasibility study early on at all? Possibly not, because some of the mistakes made seem to have been due to the lack of experience of their young founders.

Zano Nano Swarming Drone

Reason for failure: EVT not completed

(Image credit: Kickstarter)

Some of the Zano swarming nano drone‘s claimed functions never actually worked, although the idea of an ultra-small photo and HD video drone that was easy to carry was very attractive.

As with some of the other failures here, the initial prototypes over-promised a level of performance that the production units couldn’t reach. Either the founders were hiding the technical challenges they faced, or they were stalling and hoping that they’d get it right. They didn’t.

It seems that their testing and validation were lacking, and if you do not complete EVT you risk releasing a product that won’t work in real-world conditions, like the Zano. The speed at which they pulled the plug suggests that they realized that their product design was too immature to go to manufacturing and that they had overpromised.

Humane AI Pin

Reason for failure: Lack of validation of user feedback to marketing claims & pricing

(Image credit: Humane.com)

Another infamous hardware startup that crashed and burned, the AI pin is a more recent innovation surfing the wave of AI to power a wearable pin (badge?) that would be a smartphone killer. It was a $699 and $24/month subscription screen-free device that boasted advanced optical sensors, AI processing, and a unique Laser Ink Display to show information, and AR experiences through hand gestures and voice commands, and project its interface on the wearer’s palm.

The AI pin was released in April 2024, and according to The Verge, “between May and August, more AI Pins were returned than purchased.” They went on to mention its damning reviews:

At launch, the AI Pin was met with overwhelmingly negative reviews. Our own David Pierce said it “just doesn’t work,” and Marques Brownlee called it “the worst product” he’s ever reviewed.

The AI pin initially sold units, with around 10,000 hitting the market, so how did they get it so wrong and end up with large numbers of cancellations, product returns, and poor reviews? It may be something to do with the founders ignoring early feedback about the product itself:

Humane’s leadership appears to have ignored some warning signs that those bad reviews were coming. After a small group of testers — which included the cofounders’ parents and friends, several investors, and employees — received Pins prior to the device’s public launch, many voiced concerns about the product. One alpha tester contacted customer support to describe the product as “disorienting” and “frustrating” and described the many ways the product failed to replicate abilities shown in demo videos. A source said the early feedback “ripped through the company like a bullet.” They launched the AI Pin anyway.

So, despite feedback suggesting that the design was problematic and the device was not easy to use, they went ahead through development and brought it to market anyway. The complexity of what was supposedly a V1.0 product would have been a millstone as well, as the more complex designs are and the more specialized parts a product uses, the more risks of difficulties in mass production resulting in quality and reliability issues there may be. The high purchase price and subscription cost certainly wouldn’t have helped sales, either. So was the product too ambitious for a version 1? Maybe so.

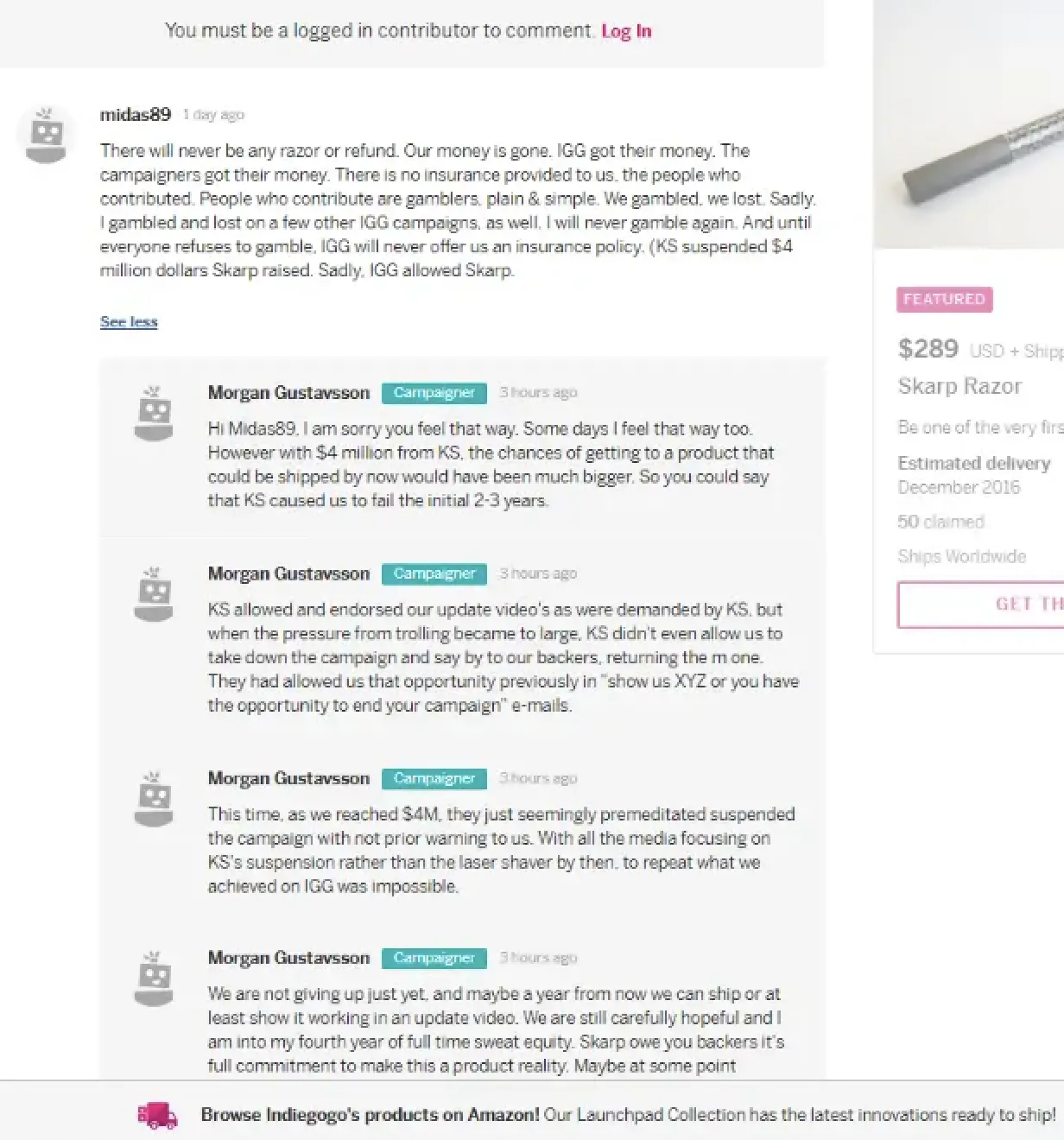

Skarp Laser Razor

Reason for failure: No feasibility study, sold the promise of an impossible product to backers, and had no way to industrialize it.

(Image credit: SkarpTechnologies.com)

The Skarp Laser Razor was marketed as the “razor of the future,” a revolutionary razor that did away with traditional blades, offering an “irritation free, incredibly close shave.” It promised a cutting-edge experience without the nicks, cuts, or razor burn one gets with traditional shaving. The campaign on Kickstarter raised over $4 million before the product was kicked off the platform…cracks were already starting to appear. They then relaunched on Indiegogo, raising a further $500,000.

So, we know that men and women loved the idea, after all, what’s not to like about an irritation-free shave?

The big problem was that the founders couldn’t match the promises they made in reality.

Despite the very successful launch on Kickstarter, the platform scrutinized the product and decided that one video of the laser just about cutting a few hairs didn’t constitute enough evidence that the startup had a proper prototype. Wired writes:

And given that Kickstarter requires projects to have working prototypes in order to accept funding, that wasn’t enough for the campaign to be successfully completed on the platform. The site declared the project was “in violation of our rule requiring working prototypes of physical products that are offered as rewards” and promptly cancelled the page.

With the removal from Kickstarter, the founders lost the $4m in backing, but Indiegogo provided the funds regardless of whether the product launched or not. So, although less than before, the founders still had half a million dollars which was still over 254% of their initial funding goal.

Skarp blamed Kickstarter and the loss of their large amount of funding for preventing them from getting to market, as you can see from this update sent out by one of their team:

But although the loss of $4m hurts, they still exceeded their own funding goal on Indiegogo, so that excuse doesn’t really wash.

So, if they had the funds, why did they fail?

The Laser Razor ultimately failed to deliver on its core promises because the laser technology wasn’t as advanced as they would have had us believe. They overpromised and underdelivered and were never able to get the laser working correctly. The one video was a ‘proof of concept’ prototype and showed the laser struggling to cut hair, and that was as far as they got.

Will King, their CMO, stated in this CNet article:

“King says the goal is to produce an initial prototype run of 5,000 units and ship those to backers by the end of the year [2016]”

This isn’t as impressive as it sounds, as that’s producing 5,000 pieces with prototype manufacturing processes which confirms that they had not figured out a way to industrialize the product, either.

The product idea, although really cool, was too ambitious for the available laser technology, and was doomed to fail when they couldn’t even make a working prototype.

The founders pressed on with good marketing and encouraging messages, but some might argue that they sold the public a dud and should have been more transparent about the difficulties they were facing during development. The project was basically dead by around 2018 and now, in 2024, it is telling that there still isn’t a laser razor on the market. Perhaps the founders running a feasibility study upfront could have saved backers a lot of money and stress?

Conclusion

We keep repeating the importance of following a structured NPI process and not skipping any of its steps, and we will probably never stop doing so. These high-profile failures demonstrate in a tangible sense why that is.