Both OEMs and CMs follow different DFM approaches. Let’s look at what Design For Manufacturing is, its benefits, and how the two different manufacturers’ approaches will affect you.

What is DFM?

Design for Manufacturing (DFM)’s goal is optimising the product design to be manufactured & assembled relatively efficiently and easily. During the product design phase, the design engineers will focus on designing the product with the materials and components, tooling, production processes and techniques, and assembly processes to be used in mind. The goal is to allow it to be made more efficiently and with mature processes (in other words, without a high risk of quality issues).

We explained DFM and DFA in this video on Sofeast’s YouTube channel:

Some DFM examples

The product may be designed to use fewer parts that need to be fastened in order to save time on the assembly line and make the product simpler overall, avoiding using a certain finishing like anodizing on a metal part that is cast (since it is very hard to make it look nice in a consistent manner), or perhaps there might be a focus on common off-the-shelf parts that can be easily sourced and assembled as opposed to custom-made parts.

DFM’s benefits

DFM provides the following benefits:

- Reduced manufacturing risks and problems, leading to better product quality

- Improved efficiency and smoother production

- Lower costs

- Faster time to market

How OEMs and CMs follow different DFM approaches

Depending on the type of manufacturer you work with to bring your new product to market, you will probably find that they follow different DFM approaches. Let’s focus on OEMs and CMs (Contract Manufacturers), as they’re two common manufacturer options that behave in a different way towards customers.

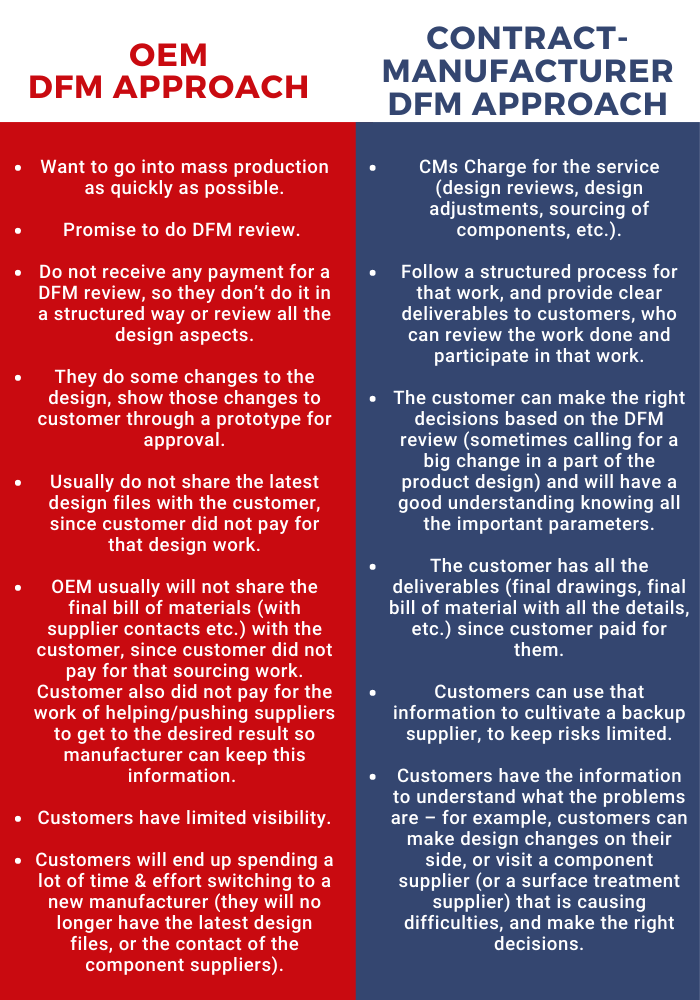

An OEM will develop a customer’s product with often little to no input from customers aside from their design. Their regular business model is to do product design, development, and sourcing work ‘for free.’ However, they will seek to retain control of the deliverables as they feel that this is theirs since ‘they paid for it.’

A CM works on behalf of the customer. The customer pays for all activities throughout the process of going from design to production and receives all deliverables. The CM will not try to keep important information such as product designs and BOM from the customer.

Both OEMs and CMs may follow DFM approaches, but they vary due to how the two types of manufacturers generally operate:

As you can see, both types of manufacturers follow a DFM approach, which is positive, but the OEM will often do this ‘for free’ and any subsequent changes to the product and BOM will likely be seen by them as ‘their IP’ and won’t be shared with you. Fundamentally, this leads to a lack of control over your product and project. On the other hand, if you are satisfied with this kind of relationship, at least in this case a good OEM will follow a DFM approach and make positive changes to the product.

The Contract Manufacturer will usually work in an opposite manner. They will charge you for the DFM work (and it may only be a few hundred USDs for a simple product that has already been designed in full), but you will retain all of the results of their work on making the product more ‘manufacturable.’ You can not only be involved in the process, but you can also take away the updated product designs and bill of materials if you feel that you need to switch to a new manufacturer later on.

*****

We recommend the Contract Manufacturer’s DFM approach because there really is little downside aside from having to pay. You, the customer, obtain all of Design for Manufacturing’s benefits while having control over your project and product IP, and give nothing away. That’s a good trade for what is likely to be a relatively small expense when compared to the OEM’s nontransparent approach.