The cost of poor quality (and reliability) is a popular topic among quality and reliability professionals. A common argument occurs between engineers who want more funding for hiring more reliability engineers, quality inspectors, and/or test equipment to be able to do their work so that the product will be more reliable and managers who want to minimize spending and keep tight control over the budget.

“Pay me now, or pay me later.”

When we talk about the phrase ‘pay me now, or pay me later’ people have different kinds of expectations about what that may mean.

Typically in quality engineering, it means spending some money now on improving the quality and reliability of the product then you end up saving money at the end of your project when your product is mass-produced because you won’t have to spend money in post-production. On the other hand, if you don’t spend an adequate amount on improving the quality and reliability of the product then you will end up spending money on improving returned products from the field. The latter is not where you want to be, because most of the time the ‘pay me later’ costs are much more than the ‘pay me now’ as you’ll see.

So that is the phrase that is very common among quality and reliability folks when they deal with certain types of management who don’t have a quality or reliability mindset and are more driven by being first in the market, rushing the project, and cutting costs and corners on quality and reliability and testing in order to get there.

The dangers of not considering the cost of poor quality and reliability

Anytime you are spending money on improving the quality or reliability of your product there is definitely money coming out of the bottom line which may not have the support of management.

On the other hand, if you don’t spend the money at the beginning of the development in order to improve the quality of the products, ultimately it is most likely that your product will not meet the end user requirements or UX and/or the intended life expectancy. This mistake will be evident in a high product return rate and, in the worst cases, a product recall needing to be issued which will be very costly and damaging to your business (and is basically the ultimate ‘pay me later’).

What does the cost of quality and reliability consist of?

The cost of quality can be split into two categories:

- The cost of good quality & reliability – includes prevention costs (how we can prevent failures from happening) and appraisal costs (inspecting, testing, and evaluating designs, components, materials, and the product itself).

- The cost of poor quality & reliability – includes internal failures (fixing things that are failing before you even ship the product) and external failures (dealing with a high return rate and other things that are happening outside the company once you have shipped the product).

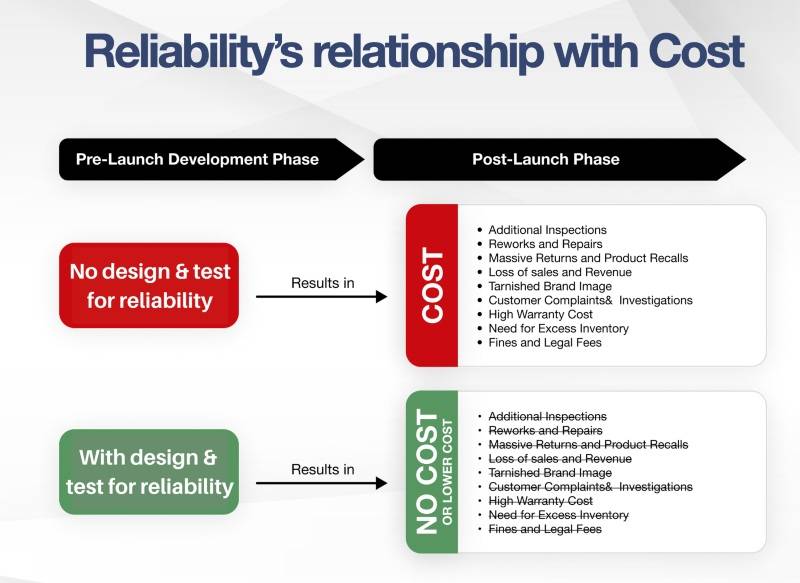

Product reliability alone has quite a considerable impact on cost as you can see here:

To reiterate, if you don’t take care about the cost of good quality and reliability elements by paying now, you’ll have to deal with the cost of poor quality which is typically much more expensive.

What’s included in the cost of good quality and reliability?

The following elements all come at a cost and should result in good quality products being made…

Prevention costs

Prevention costs during new product development have to do with planning for quality and trying to have a standardized process. Any and all of the following can make up your prevention costs:

- Training your staff and your manufacturing operators.

- Conducting quality audits of your suppliers before they start work to make sure they are capable, understand quality, and will be able to produce high-quality materials and components.

- Doing market research at an early stage so you know that you’re designing and building a product that satisfies your customers’ needs and has a legitimate place in the market.

- Process capability analysis so you have a preventive prevention methodology or processes in place within the company to check and operate within the quality and reliability and testing target (if you don’t have these it’s a chaotic scene where there are no rules or policies and people are just doing things however they want which leads to a failed project)

So prevention costs have a lot to do with quality and reliability and testing policies and how you think of quality when it comes to designing and manufacturing your product, how you work together, and just overall making a better product with a quality/reliability mindset.

Appraisal costs

In short, appraisal costs are related to inspection and evaluation costs of components, processes, designs, etc. This could include, for example:

- IQC – incoming quality inspections where you’re trying to control the quality of the parts, materials, and components coming into the factory and you don’t want any ‘bad’ parts to be mixed with good ones used in manufacturing. So this department assures that materials and components that come from outside all meet a certain kind of specification and performance requirement before they’re allowed to be used in the manufacturing or design environment.

- In-process inspection – let’s say you’re assembling a very complicated product that has many pieces and you don’t test and inspect as you go along. There’s always a good chance that at the end of the production line the product is not going to function or it’s going to have all sorts of failures and defects. So in-process inspection prevents this and typically works with operator inspection (each operator who is assembling a module is also responsible for testing and inspecting whether what they put together actually functions as it should before passing it on to the next person). For example, if the operator is adding a switch to the product there may be a jig that checks if the switch is working or not before it can be passed on along the line.

- Supplier evaluation, audit, and inspection – during design and development you need new components for your product and you need to find quality suppliers. For prototypes you might be able to buy a few components online, say, but for mass production, you need to find a quality supplier to ringfence quality and reliability in the product. Therefore, you need to do supplier evaluation and inspection and supplier audit and you need to go and visit the supplier’s facility and go through the complex audit process. This might be an ISO audit, it could be design related, focus on manufacturing, and so on. The objectives of the audit matter, but in any case the objective of the audit is to help you know if the supplier is capable of designing and manufacturing high quality and reliability components within your specification. Once you find such suppliers the next step is to approve and set guidelines for them so they understand your specification requirements. You will also set some rules within the manufacturing contract that protects you from too much financial damage in case there are massive failures, knowingly or unknowingly, from the supplier.

- Reliability testing, compliance testing, and laboratory testing – all of these are very important processes to figure out if the product you have designed meets your required specifications and the end-user requirements, too.

- Final random inspection – once you have built the product through the assembly line and they are ready to be shipped, a final random inspection (also know as a final goods inspection) should be performed. Typically it’s an AQL process that checks if the products have any non-conformances that could result in rejecting the whole lot and not shipping the product. Of course, every time you’re not shipping the product you’re not making any money so it is very important to have this final inspection as soon as the production has concluded.

- Equipment calibration – test equipment used in the lab or on the factory floor and manufacturing equipment all need to be within calibration. If an essential piece of equipment, such as a network analyzer used when designing a circuit diagram, is faulty, you might ship a product thinking that everything is fine or will at least build several of these boards which won’t work because the calibration was out of date on the equipment and what you got was out of tolerance measurements against the desired specification of the product. This leads to costly waste and can throw a big wrench within the design and manufacturing teams. Manufacturing and ISO auditors know this is critical so they always look for equipment out of calibration.

What’s included in the cost of poor quality and reliability?

We’ve already seen what makes up the cost of good quality: prevention and appraisal costs. Let’s now move on to what drives the cost of poor quality.

Internal failures

Internal failures mean that within your company there are failures which have costs associated with them.

- Product rework – after a problem has been found. These defective pieces have to go to the rework department in the factory and operators will have to rework whatever is wrong, such as boards and PCBs. Every time they do that, some can’t be reworked and will have to be scrapped. So you lose money on the extra rework time by staff and any scrap products that become waste.

- Internal scrap rates – you’ll need to keep an eye on them. I was working for a company once that had a whole room full of scraps, each costing over US$500! You can just imagine how much money was being wasted.

- Customer returns – It’s a similar story with products that are returned from the field due to customer dissatisfaction. The product return process is complex and costly process. Repairing and returning faulty products to the customer represents a huge cost because ‘bad’ products often fail before their warranty period ends, leaving you, the manufacturer, footing the bill for the return. My advice is to focus on making a product that lasts longer than the warranty period as an absolute minimum, say, a year or more (imagine you shipped one million products costing US$500 each and 20 were returned. You have to spend US$500 of your own money to either give a new product back to the customer for free within the warranty period or you have to handle, repair, and return it which can be more expensive than the selling price in some cases).

A team of test engineers will have to retest these returned products, and, depending on the volume of returns, you may end up having a whole building dedicated to triaging the returns and repairs/rework. I also once worked for a mobile phone company a long time ago that had so many returns that it actually cost them more than one billion dollars because they were handling over 1 million returned phones and they had to purpose-build a facility for it. The cost of operating that kind of facility is enormous and it’s really not worth it when you consider that ploughing just some of that money into designing and developing a better product could avoid the need for it.

After these returns come in and you’ve triaged them, engineering will have to do testing and failure and analysis on them. - Re-analysis, new tooling, and new parts being produced – Some pieces will have to go back to suppliers who will have to examine and understand what happened with their part, for example, maybe a cover’s material breaking or cracking. They will perform a raw material analysis which may result in new raw materials being required for the part, a knock-on effect of which is new plastic injection mold tooling needing to be fabricated and new parts eventually made and validated.

As you can see, this is a lot of headache post-production that can be avoided if quality and reliability due diligence is done early on before production happens.

External failures

External failures are when a customer buys a product and it fails, leaving them the job of returning it or claiming their warranty. This is an unwelcome headache for the customer, especially if they have the inconvenience of waiting for the return to be fixed or they have to travel somewhere to return the product.

- Bad reviews can be a killer for businesses – External failures like this have a huge impact on the company because they don’t just hurt the business and bottom line, but they also damage the brand’s standing in the marketplace. After all, it only takes two minutes to leave a negative review online, but the damage that causes your business is long-lasting.

An illustration of the power of negative reviews and feedback is when I worked for a company a long time ago who didn’t build a product that met the market demand and there was such an online revolt against this company that they almost went bankrupt. They had to lay everybody off, stop development, and nobody wanted to buy their product. They did turn things around, though, as they’re still in business today. But it is amazing that the impact of poor quality products hitting the field can bankrupt a company if they don’t pay attention. - Legal issues – If you have a major customer like a retailer they’re also going to be upset by products that keep failing once purchased by customers. This could lead to more scrutiny, penalties, and even lawsuits if you are in breach of what was agreed with them in contact.

They may wish to come and audit your facility and also charge any penalties they have to pay to their customers back to you. Based on your contract with them they may even take legal action if an order is not satisfactorily filled, which is a serious problem caused by external failures in the field.

The cost of poor quality and reliability, in these cases, could send a company to bankruptcy.

Summing up…pay now, don’t risk paying later!

Believe it or not, there are still a lot of times I see new customers come to our facility or contact us and they say: “I made a mistake. I didn’t have the time or money to spend on quality and reliability and now we’re having huge failures. We don’t know how to control it.”

Whether or not to ‘pay now’ to reduce the risks from the cost of poor quality is a big dilemma for the majority of entrepreneurs who are new to starting up a small brand with a great new product idea in mind because they can be on a tight budget.

However, we always recommend that you need to do more reliability testing and make sure the reliability test plans and test cases pertain to the worst-case and use-case scenarios in your products so you can find the issues during the new product development process and fix them so they won’t be seen again in the field.

By the way, it isn’t only SMEs that can fall into this trap. We’ve all heard of the famous catastrophic failures with the exploding Samsung Galaxy Note 7 smartphone and the Boeing 737 Max aeroplane which crashed more than once killing hundreds, and just now in November ’22 Tesla has had to recall 320,000+ vehicles due to a problem where the tail lights sometimes don’t light up when needed (it goes without saying that this is a risk to passenger safety).

In a nutshell, this is all about understanding the difference between the cost of good quality and reliability and the cost of poor quality and reliability. Both have a cost, but making sure that you take care of any potential quality and reliability issues with the product up front and then you will not see those issues in the field is the cost of good quality and reliability. If you do proper design, optimum reliability testing, follow all quality and industry standards in inspection and manufacturing guidelines making sure that you follow good manufacturing practices such as how to improve your yield, this will cost money, but take it from me that it’s going to be less than paying later to fix problems found by customers once the product has been manufactured and sold.