Product Teardown and Design for Assembly and Disassembly Improve Product Reliability and Quality

How do continuous product teardown, disassembly, and reassembly, improve reliability and quality? Let’s find out here…

PCB Design or Enclosure Design: Which to do first?

Should you do PCB design or enclosure design first for your new electro-mechanical product? That’s a question which bugs many […]

Corrective Actions and Preventive Actions (CAPA) Guide

In this post, I’m going to introduce a helpful strategy for importers manufacturing in China or elsewhere to reduce quality […]

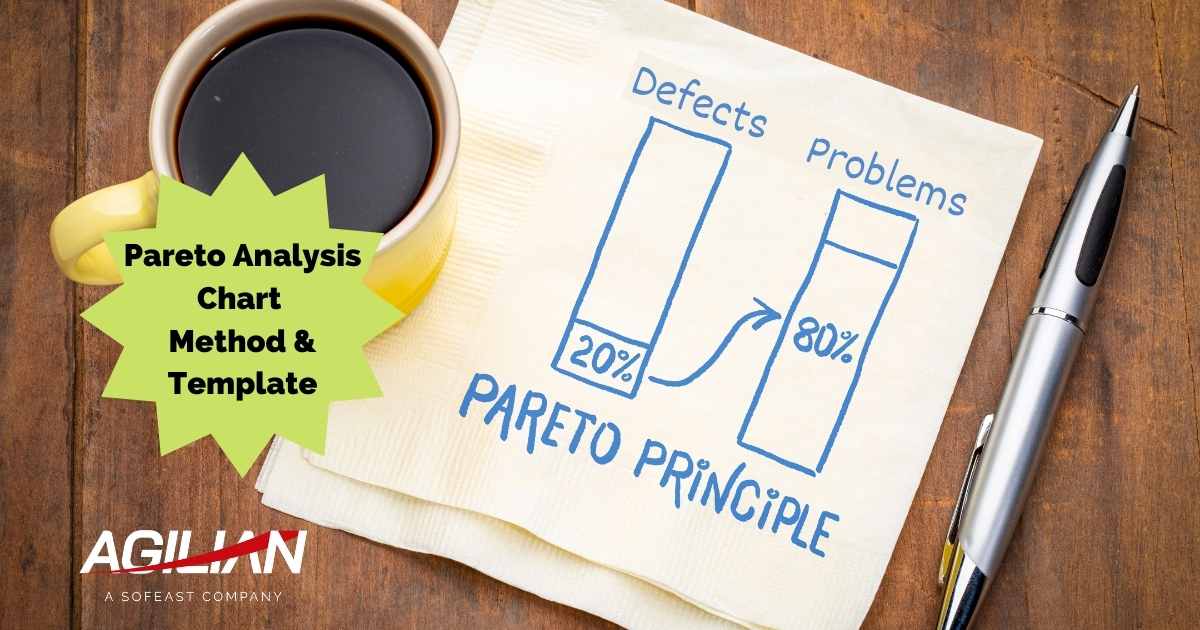

Conducting a Pareto Analysis | Method and Template

What is the Pareto analysis? Many engineers working in manufacturing turn to conducting a Pareto Analysis when they want to […]

CTQ Components: How Component Engineers Manage Their Quality

CTQ means ‘Critical To Quality‘ and you can actually use that methodology for just about anything that you want to […]

dFMEA: 8 Secrets for a Successful Implementation

In this post, we’re going to explore the dFMEA or design failure mode and effects analysis. This is a must-use […]

How To Achieve ‘Final Hardware’ Faster?

What is final hardware? Final hardware really means a combination of software and physical hardware (in the case of many […]

Mistake Proofing and Why it’s so Important for Manufacturers!

Mistake proofing is an important tool used by manufacturers for analyzing the assembly process and finding ways in which errors […]

Product Development Lifecycle: Why and How to Reduce its Time?

Let’s look at how to reduce the product development lifecycle time and the benefits of doing so to importers who’re […]

What To Do If You Have A High Product Return Rate? [6-step Process]

What actions should you take if you find that you have a high return rate on your new product that’s […]

What Is Six Sigma For Manufacturing And Its Main Goals & Benefits?

Six Sigma is a systematic approach to reducing variations and improving processes in all sorts of environments, particularly in manufacturing. […]

5 Main Reasons For A High Product Return Rate

In today’s blog post we’re going to examine some of the key reasons for a high product return rate, so […]

You NEED to do product qualification BEFORE mass production!

Let’s discuss the ONE key type of activity that needs to happen during the NPI process in order to go […]

Drop Testing | 3 Tests That Can Save You A LOT Of Money

Here we’re focusing on product testing, specifically, drop testing using smartphones as a typical example of a consumer electronic product […]

Should I use a Golden Sample or Limit Samples?

During the new product development phases depending on the type of products that you make engineering teams are faced with […]

![What To Do If You Have A High Product Return Rate [6-step Process]](https://www.agiliantech.com/wp-content/uploads/2022/07/What-To-Do-If-You-Have-A-High-Product-Return-Rate-6-step-Process.jpeg)