Are you a startup, and are you developing a new hardware (physical) product? Are you planning to raise money to finance your project?

Even if you have started developing a new product idea, you have some way to go before you’re ready to speak to a manufacturer and start production. Let’s go through the 9 new product development milestones you’ll pass en route to getting your product to market.

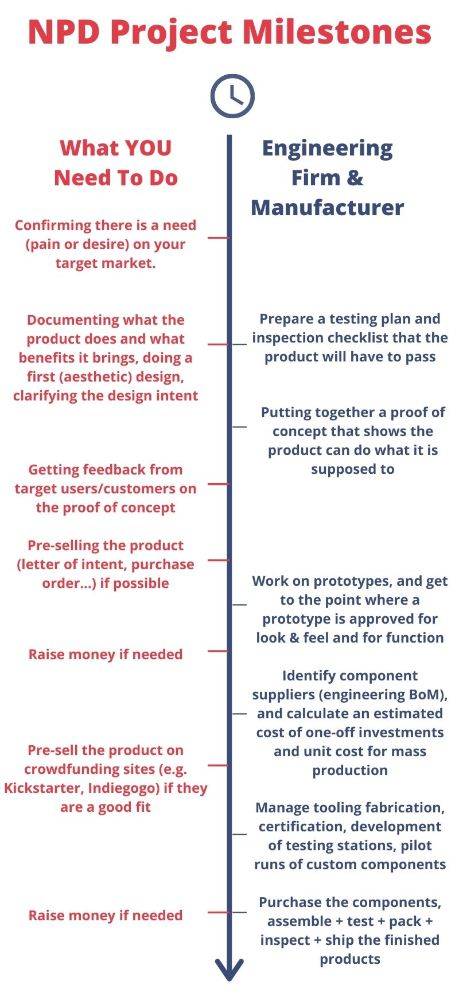

New Product Development Project Milestones

There are many milestones that the typical hardware startup needs to hit before they reach the mass production stage, including what can be described as a lot of ‘homework.’

The typical investor becomes more interested as you complete milestones that prove your project is less risky and is getting closer to the desired result – a profitable company that has real customers and some unique intellectual property.

The new product development milestones that make sense may vary from project to project, but investors consider them as fairly consistent. This is generally applicable for projects that represent between 100,000 and 1.5 million USD in development budget.

Here is a graphic that shows in order who needs to do what and when throughout a typical new product development project. The milestones showing your actions are shown in red and the actions that we typically perform are shown in blue:

Breaking down the process of going from new product design to mass production

Let’s go through the typical steps from new product design to production.

Step 1: Confirming there will probably be market demand (by the founders)

Talking to potential customers and decision-makers is often quite insightful. It is usually the right first step. Many products are launched and don’t meet any demand (and the entire project is an enormous waste of time and money). That’s an important risk to address.

Step 2: Putting some thoughts into what a solution would look like, how it would work, etc. (by the founders)

If you are not motivated enough to spend the time to educate yourself on the technologies and materials related to the product, both manufacturers and investors will see that as a red flag!

Working on the aesthetic design, without going into all the small details, usually makes sense at this stage. The designer will need a clear brief, to understand what you have in mind.

Step 3: Translating performance needs into more objective requirements

Let’s say you want to develop an e-bike. Instead of “it can go fast”, write “it can get up to 25 mph on flat terrain”. Instead of “it can last a long day trip”, write “battery can last more than 5 hours if the bike keeps going at 15 mph on flat terrain with no stop and a passenger of 150 Lbs”.

This is a critical link between the benefit to the user and the information engineers need to work with.

Step 4: Building a ‘proof of concept’

People who think of a new product want to have a prototype as early as possible. It makes sense. But, if you can’t find a product that is relatively similar in terms of functionality, the first step is to make a crude prototype that will “do the job”. One purpose is to learn from it and, if needed, to do a few iterations in order to improve the design.

Step 5: Again, confirming there will be demand for such a product, and if possible pre-selling that product (by the founders)

Another purpose of the ‘proof of concept’ is to collect feedback from potential customers (“the product will work like this, and of course we still have work to make it look nicer, be more reliable, and so on.”)

You really want to minimize the risk of bringing something to market and find out that your target customers don’t see any value in it. You also want to get as much constructive feedback as possible and improve the design.

Step 6: Building prototypes and testing them as per steps 2 & 3, and confirm the technical feasibility

Now is the time to work on prototypes. For a relatively complex product, it may take 3-8 iterations before a look-alike and work-alike prototype can be confirmed. (And remember to do testing as per step 2.)

All this can be handled by a design firm, and a company like ours is involved to confirm the feasibility and sometimes to work on some aspects of the engineering work. For certain projects, we can manage the whole development process and use external resources (in a transparent manner) where needed.

On your side, you really need to have a clear and documented quality standard by this step.

Step 6 bis: Identification of suppliers, which leads to estimates of pricing, MOQ, lead times, etc.

To build the prototypes, parts need to be procured. As the engineers get closer to a final prototype, it is important to get those parts from qualified suppliers (i.e. capable of mass production with high quality). The end deliverable is the engineering BOM.

Step 7: Again, pre-sell the product if possible, for example on Kickstarter (driven by the founders)

I get back to this again and again. As much as possible, you need to sell your new product before it is fully produced! For certain consumer products, crowdfunding is a great way to address this.

Step 8: Handle all the pre-production work (tooling, certifications, process engineering, pilot runs, reliability testing…)

This is the step when you really need to be working with the company that will manufacture the product. (There are many things you might want to check in order to vet a manufacturer, and we created podcast episodes about this – here is episode 1 of that series.)

You are also encouraged to be involved in these steps, but a supplier that has done this many times in the past will save you time and headaches.

Step 9: Mass production

This is all handled by the manufacturer you have chosen — for example Agilian. We welcome our clients to follow the production launch on-site if they can travel. Some products come with special challenges, and it is good to be able to adjust the process on the fly if we were not given sufficient time in pre-production to address these issues.

—

Following these steps from new product design to production is hard work. But will increase your chances of bringing your new product from design to production and to market successfully. That’s also the way investors look at it, and that’s why they look at many of these steps as significant milestones.

Editor’s note: This post is an adaption of QualityInspection.org’s post.

Are you planning to launch a new product soon?

Our in-house R&D department and manufacturing specialists can help you make sense of the work you need to do to get your product idea to market quickly and within a reasonable budget. Get in touch with us to discuss your project and we’ll let you know how we can help manufacture it in China and explain the new product development milestones you’ll go through for your individual project!

About Renaud Anjoran

Renaud is a recognised expert in quality, reliability, and supply chain issues and is Agilian's Executive VP. He has decades of experience in electronics, textiles, plastic injection, die casting, eyewear, furniture, oil & gas, and paint. He is also an ASQ-Certified ‘Quality Engineer’, ‘Reliability Engineer’, and ‘Quality Manager’, and a certified ISO 9001, 13485, and 14001 Lead Auditor.