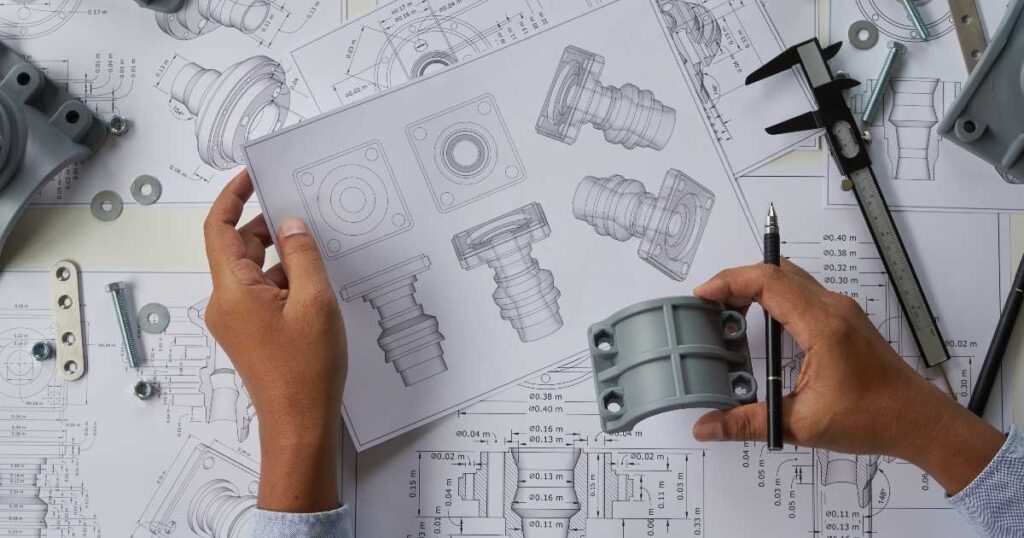

I touched on numerous DFM tips spanning several topics which I summarize below:

1. Make sure you do your homework

2. Don’t over-complicate your product

3. Increase your chances that manufacturers will take you seriously

4. You can ask a manufacturer for feedback on your design, but there are many well-known ‘do’s and dont’s’ that you should know of

******

Do you have any DFM tips to share that you’ve picked up over the years when launching new products? Comment and let us know!

You may also like to read:

- Common DFM Improvements On Plastic Injection Molded Parts

- What Common Improvements Can DFM Make To Die Cast Parts?

Are you planning to launch a new product soon?

Our in-house R&D department and manufacturing specialists can help you make sense of the work you need to do to get your product idea to market quickly and within a reasonable budget. Get in touch with us to discuss your project and we’ll let you know how we can help manufacture it in China!

About Renaud Anjoran

Renaud is a recognised expert in quality, reliability, and supply chain issues and is Agilian's Executive VP. He has decades of experience in electronics, textiles, plastic injection, die casting, eyewear, furniture, oil & gas, and paint. He is also an ASQ-Certified ‘Quality Engineer’, ‘Reliability Engineer’, and ‘Quality Manager’, and a certified ISO 9001, 13485, and 14001 Lead Auditor.