There is a common belief among many importers that Chinese factories are unable to help during the design phase of a new product. As a result, the importer typically works on a design on his side and then asks the Chinese side to make it a reality.

The reality I see is, the more complex the product, the more the buyer needs input from the manufacturer (who has more intricate knowledge of a process or material). I listed 11 ways the supplier can help.

Early Supplier Involvement

1. They can share guidance with you.

A very mature supplier would be able to share a plethora of informational guides with the design team such as:

- Common components – standardization

- Material and process limits

- Best practices from a production point of view

- New production methods and techniques

- Cost saving options

2. Reduce the cost of design changes.

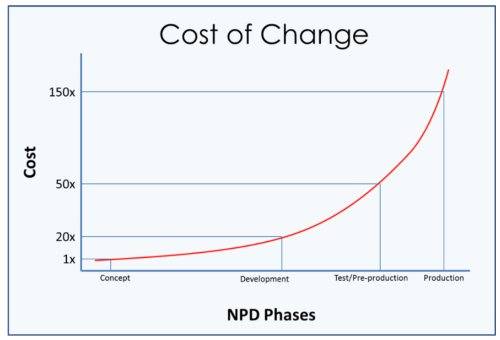

Another key attribute to getting your supplier involved as early as possible is the cost of design change. The cost change increases the further into the NPI process (also known as new product development or NPD) you get, so understanding limitations from a production point of view while in the design phase could save you not just from a financial aspect but also from a schedule point of view.

As you can see below, the later you make changes to a product design, the more costly it becomes, for example, at a later stage once injection mold tooling has been created it might need to be re-machined to reflect design changes and this is very expensive work:

Before Production Starts

Before production starts in the new product development or NPI stage, consider the following activities that can reduce risks in the product design:

3. Design for Assembly

Ask the team on the factory floor (operators, managers, etc) about any difficulties they face when making your product. If practical, modify your design to be easier to assemble using a DFA approach which might lead you to use fewer parts overall, reduce the number of custom parts in the product by using more common off-the-shelf ones instead, use adhesive instead of fasteners that take time to screw in, etc. Again, easier production makes for faster deliveries of higher-quality products, and the supplier will be less inclined to push prices up in the future. (Note: this may also be done earlier before production starts, but using engineers’ experience instead of real post-production feedback from the factory to influence design changes).

Learn more about DFA (assembly) in this video:

4. DFM (Design For Manufacturing): this approach look at the processes they and their key subcontractors have, and design a product that will be easy to manufacture. For instance, the focus will be on how easy it is to manufacture custom components and assemble the final product quickly and easily. The benefits are lower costs, better quality, fewer headaches and delays once the product starts being manufactured.

Learn more about DFM in this video:

5. DFP (Design For Procurement)

Ask the supplier if they have suggestions for changes in materials/accessories. (The supplier will probably suggest these changes on their own.) Be very careful with components purchased “on the local market”. They are usually cheaper but are not always your best choice. Make sure you audit the second-tier suppliers if you plan to purchase high volumes.

6. dFMEA

Sit down for a design FMEA with the most experienced engineers at the factory (ask “what can go wrong?”). In case the buyer has no technical experience, for best results, he should hire an engineer who has experience doing FMEAs and can jump-start the meeting with a few suggestions about what the possible failure modes might be. Doing this very early reduces the risk of such failures making their way into production because we’re brainstorming and heading them off before issues are caused. If need be the engineers will suggest the product design can be adjusted to stop the riskiest failures from occurring.

7. HALT testing

Send a few samples to a testing lab for HALT testing, or do it in the factory’s internal laboratory if they have one. A Highly Accelerated Life Test repetitively tests the product’s functions in a controlled chamber that can simulate heat, humidity, and more. For example, you could take a product and run it at its maximum operating conditions along with combined stresses; for example, running it at high temperature, but also with vibration and humidity along with high current or voltage conditions to see if the extreme stresses caused any failures and evaluate those failures.

This is beneficial because it will tell you the product’s common failure modes and their root causes, what its realistic operating limits are, and how far outside of those limits the device can be pushed before it fails and breaks.

8. pFMEA: Sit down with the most experienced engineers at the factory and examine the production processes. They, rather than the design, could be causing defects, for example. Not only will it push them to improve their production processes, but it will probably also give them an opportunity to voice where the difficulties lie in making your product. For example, controls such as a mistake-proofing fixture could be included in a stage of the process where the operators have mistakenly been fitting a component the wrong way around.

9. Document everything

Give it to your supplier in written form (with as many photos, drawings, charts etc. as possible), and ask for confirmations and suggestions. In China, many problems only come up to the surface when a manager is asked to confirm something in writing.

After Production has Started

Now that production is underway there are still things we can do to reduce problems in our product design. At this late stage, it would be preferable that you don’t suffer from defects, product returns, or in the worst case need to recall products from the market, but if issues are occurring you can do the following and fix the design accordingly:

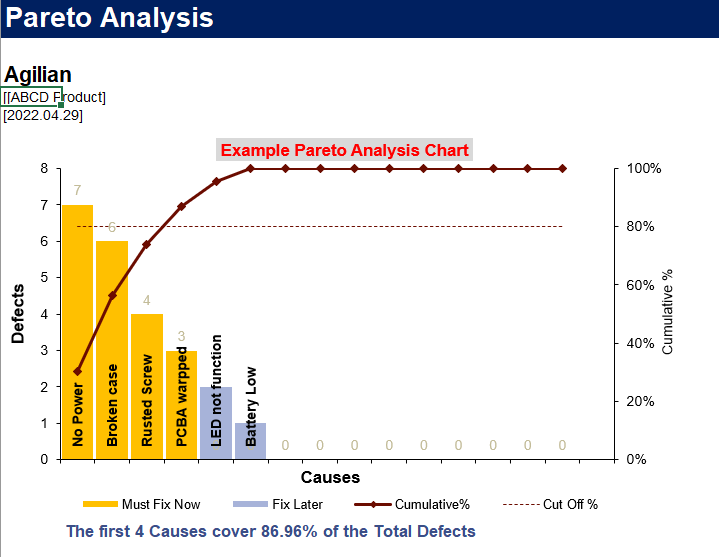

10. List common defects

List the defects and rank them by quantity (using a Pareto chart), look for the root causes (fishbone diagrams, asking “why” 5 times…) of the most frequent defects, and think of the issues that are caused by your design. Then modify your design if that’s practical. Note that the people who can best point to root causes are the operators, engineers, and managers working at the factory.

Here’s an example pareto chart that shows the most common defects (the 20% that cause 80% of the problems) that can then be fixed most urgently:

11. HASS testing

Send a few samples to a testing lab for HASS testing to monitor the manufacturing process, or do it in the factory’s internal laboratory if they have one. HASS (Highly Accelerated Stress Screening) is done during manufacturing and will highlight manufacturing defects that can cause failures during normal use of the product (including storage, transit, etc). Stressors (such as vibration, environmental changes, rapid thermal cycling, etc) are applied to the product that fall within its overall operating capability (as defined during HALT testing) but above its normal specifications to find defects that may have been caused during the manufacturing process before it reaches consumers’ hands. Due to the more normal nature of the stressors, it is not very destructive unlike HALT, and so if products do fail we can see how they might not be as reliable when in normal use by consumers. The benefits of HASS are that it is a kind of safety net that can find unreliable products, reduce the risks of returns, poor reviews, and recalls, and lead to improvements in the manufacturing process once products are mass-produced.

Next steps…

If you’re looking for more information or help to reduce the risks of your product design leading to quality and reliability problems once you get to manufacturing, let us know about your project and concerns by contacting us. We will be happy to talk about your situation and provide some advice.