Our customers often ask us how to get a UL certification mark for their products, and they often believe they need to work with UL (Underwriters Laboratories) themselves to achieve certification. That’s not correct.

They also ask us very often if such or such testing or certification is mandatory. The answer is ‘it depends.’ Let’s clarify all this in the following Q&A sections.

Q: What is the purpose of going through the process of putting UL certification mark on a product?

The purpose is to assure users and buyers that they are using a product that does not present electrical safety hazards.

Over the years, a lot of properties have been damaged by fires started because of poor electrical safety, and many people have been killed or injured by electric shocks, charger explosions, fires, etc.

Other typical compliance requirements for electrical products are restrictions/bans of chemical substances (for the sake of human health and/or the environment), electromagnetic compatibility, and a range of product- or application-specific requirements.

Q: Do USA retailers require the UL mark for all electrical products?

The short answer is no, for two reasons:

- Walmart and others accept marks that are equivalent to the UL certification mark. Search their websites and you will see products with ETL, TUV, MET, SGS, and other marks. (More about this below.)

- They are mostly concerned about products that plug into a mains socket (in other words, into a wall). If your product only uses a USB cord to charge from a power source, this requirement does not apply.

Q: Can only UL deliver such a mark themselves?

No. You have other options that are typically cheaper and have exactly the same legal standing.

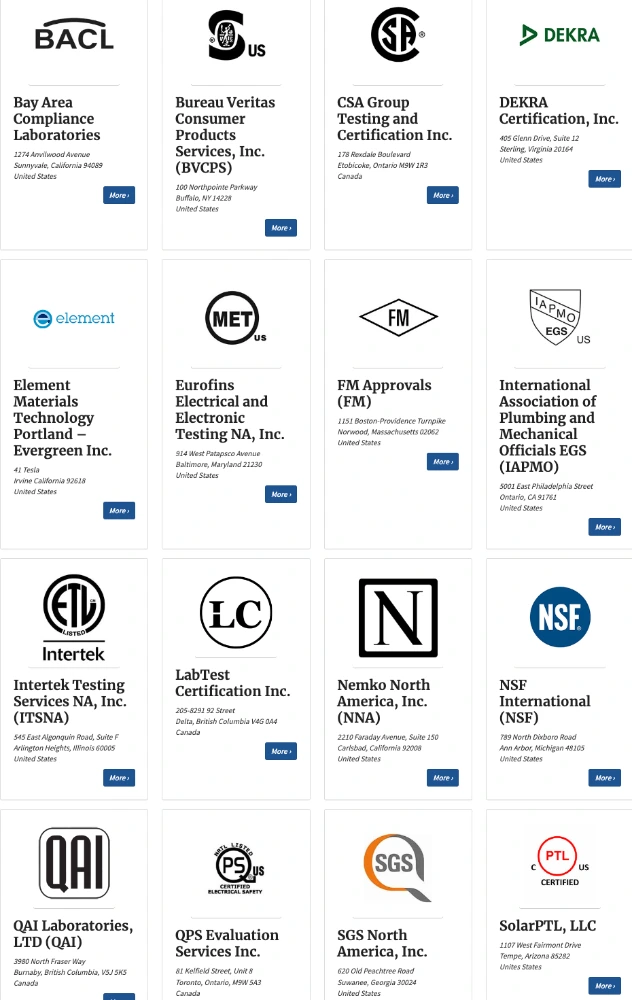

The Occupational Safety and Health Administration (OSHA) has ‘recognised’ (in other words, accredited) other testing organizations in the USA and Canada to deliver their own marks (in other words, certify) on electrical products. The list of their marks is shown here. Here are some of them.

UL had a near monopoly until the 1970s, but is now one of many options. Their registration mark is the most famous and it may be useful in re-assuring some buyers/consumers, but there are some very good alternatives, some of which (ETL, TUV…) are somewhat famous, too.

Q: So, why do we keep talking so much about UL?

The proper way to mention this topic is to write about certification to UL standard(s). UL is still the publisher of the standards for the USA, so, for that reason, you will typically still see “UL” on test reports.

Note, some of the standards published by UL are actually simply a re-publication of standards developed by the IEC in Switzerland.

Example: IEC 62368-1 was adopted as UL 62368-1 in the USA and as EN IEC 62368-1 in the EU.

Conversely, some UL standards don’t have an equivalent IEC standard.

Example: lithium battery cells can be tested against IEC 62133-1 or -2 (depending on their chemistry) and/or UL 1642, and those standards are not equivalent.

Q: What are the other accredited testing laboratories?

See the list of “NRTLs” on https://www.osha.gov/nationally-recognized-testing-laboratory-program/current-list-of-nrtls.

If you are unsure which one to pick, let us know, as we regularly work with a few of them.

Q: When is it necessary to certify a product for electrical safety for sale in the USA?

Certification to applicable UL standard(s) is mandatory if the product gets plugged into an AC electrical outlet. Note that, in some cases, picking a pre-certified module (typically a charger) will help you tremendously.

In other cases, in our understanding, certification to applicable UL standard(s) is not mandatory if the product is not to be used in a workplace (remember, the OSHA regulates ‘occupational safety’ — see this page for more details about some of the products it regulates), but it is highly advised in all cases.

Note that many retailers, and in most cases also insurance companies, require some evidence that the product is safe, so in the end you might still be forced to pay for it.

Q: If it’s not a must to pay for a famous mark, but we still care about our product safety, what should we do?

First, there is a lot more than testing involved here. The product has to be designed in a way that satisfies the requirements of the applicable technical standard(s).

Sourcing of components/modules is also very important. Components made by reputable companies are usually better designed, manufactured with better control, and, overall, are much safer.

When it comes to working with laboratories, some of our customers have simply paid for product testing (not for certification, for a mark, or any of that) at a reputable lab. That’s probably the most basic way to reduce risks. They can still show the test report and, provided the report is passed, communicate that the product passed testing to UL standard(s).

Finally, there is an element of post-market surveillance, ongoing assurance about manufacturing, etc. that should not be overlooked. That’s why UL, ETL, CSA, and other accredited labs usually have to conduct routine inspections at the factory — it’s not just about a one-time testing job!

Also, changes to the product design, bill of materials, etc. have to be evaluated carefully — in some cases a round of re-testing might be needed.

Q: How about Canada?

There is no automatic acceptance of certifications for the USA for sale in Canada, even though the systems are rather similar. So, be sure that the mark you pay for will also be accepted for Canada. It is often a different mark (for example, “ULc” vs. just “UL”) coming from the same testing & certification process.

In our understanding, the biggest difference between the USA and Canada is that the latter requires certification for all products that plug into a socket (not just those for the workplace).

This is a deep topic, as different jurisdictions within Canada may have different restrictions. As written on the SCC website:

“Electrical safety falls under the responsibility of provincial and territorial authorities. Provincially recognized certification marks confirm compliance of products that have an electrical component to the Canadian Electrical Code (CEC) CAN/CSA C22.1 published by the CSA Group.

Certification marks are issued by SCC-accredited product certification bodies. Any certification mark originating from an SCC-accredited US-based certification body needs a small “c” in front of the mark to indicate to the user, inspector and retailer that, even though the mark is from the United States, the assessment of the product has complied with the CEC. To obtain the listing of provincial and territorial recognized electrical safety certification marks, contact your provincial or territorial electrical safety authority.”

Q: What documents are usually needed, to apply for a mark from UL, ETL, or equivalent bodies?

For a good explanation of what’s required, read North American Product Safety & Compliance Certifications And Requirements For Electronics (UL, ETL, and CSA) on the Sofeast website.

Q: Does all the testing have to take place in the lab whose mark will be on the product?

It is usually the case, but that’s not a must. Other test facilities (at a factory, at another testing lab, etc…) may produce acceptable results under certain conditions. To simplify, the lab might have to be pre-approved, or the testing might have to proceed under specific supervision.

Make sure to ask your chosen certifying body (aka the NRTL) what their criteria are, ahead of time.

Q: If we work with UL, is there just 1 type of certification, or will we have to choose among several options?

It is better if you know what you want first.

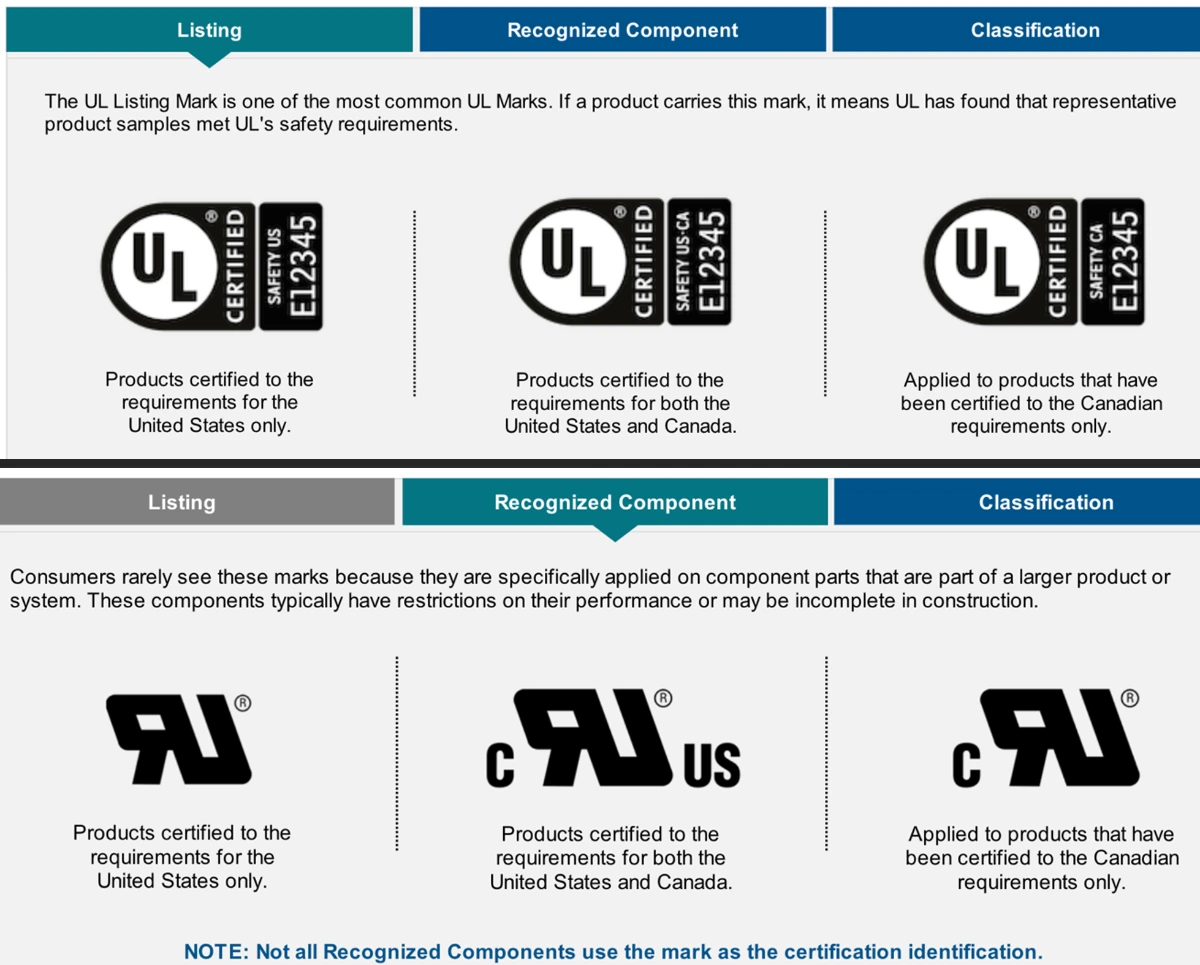

There are 3 types of UL certifications:

- Listing

- Classification

- Recognized component

See below what the different marks look like and an explanation of each:

Your product may feature different marks, but they can usually be found labelled on the underside of products, according to the U.S. Consumer Product Safety Commission (Source: WSJ – Don’t Burn Your House Down. Here’s How to Buy Safer Electronics):

Look for a certification label from a nationally recognized testing laboratory, markings such as UL, ETL, CSA or SGS, said Patty Davis, a spokeswoman for the U.S. Consumer Product Safety Commission. These typically appear on packaging or the product itself, which is why it is sometimes easier to assess product quality in-person.

Q: How can the UL mark be displayed on relevant products?

According to the WSJ article, referred to in the prior question, the UL mark is sometimes attached via hologram to demonstrate authenticity and product safety (even though this is not very common, yet):

Certain kinds of products have a special UL holographic sticker as an extra layer of authenticity, including holiday lights, e-scooters, e-bikes and vapes.

When it comes to e-scooters and other mobility devices, the UL label is particularly important, says the CPSC. A 2022 letter from the agency highlighted a “rise in fires and other thermal events” and urged manufacturers and retailers to adopt UL certification to “significantly reduce the risk of injuries and deaths.”

UL Solutions puts devices through a range of testing, said Michael Sakamoto, a safety specialist at the firm formerly known as Underwriters Laboratories. If a product gets hot, the enclosure should be able to withstand the high temperature. If a device malfunctions, it should shut down. If it is made of plastic, the plastic shouldn’t break after a short fall and expose live electronics.

Additional reading

You may also like:

- 11 Common Electronic Product Certification And Compliance Requirements

- UL Compliance: Does YOUR Product Need UL?

- US Consumer Electronics Compliance Basics

- FCC Compliance Tips for Electronics

Disclaimer…

We are not lawyers. What we wrote above is based only on our understanding of the regulatory requirements. Agilian Technology does not present this information as a basis for you to make decisions, and we do not accept any liability if you do so. Please consult a lawyer before taking action.