- What we do for you

- About Us

About Us

- Why Choose Us

Why Choose Us

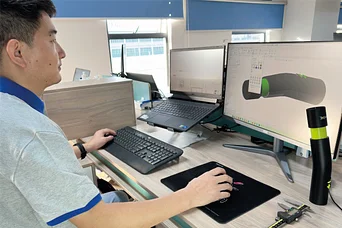

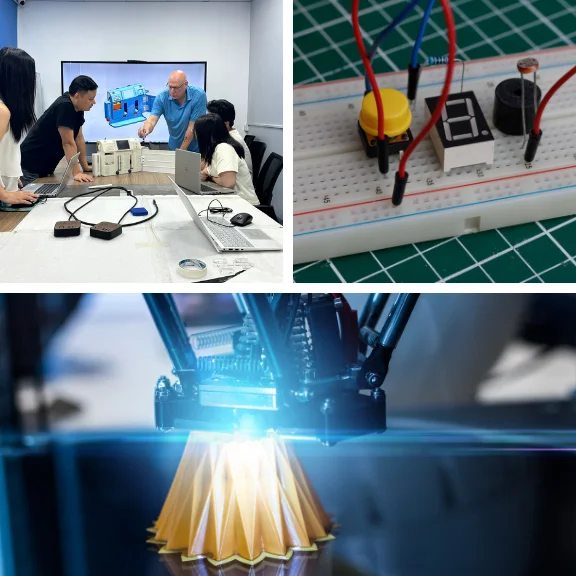

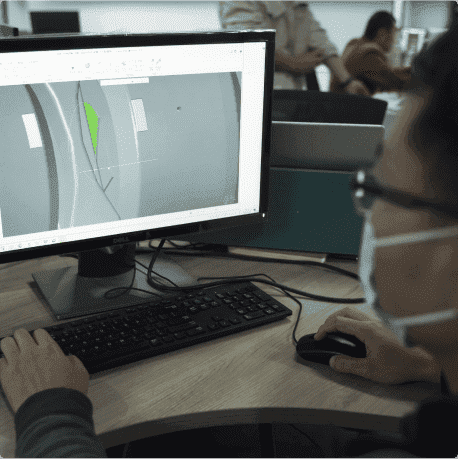

In-house Equipment

Other Important Topics

- Resources

Resources

Blog & Social Media

- Contact Us

- What we do for you

- About Us

About Us

- Why Choose Us

Why Choose Us

In-house Equipment

Other Important Topics

- Resources

Resources

Blog & Social Media

- Contact Us

- +86 755 8285 8796

- +86 755 8285 8796